Composites: The future lies in space

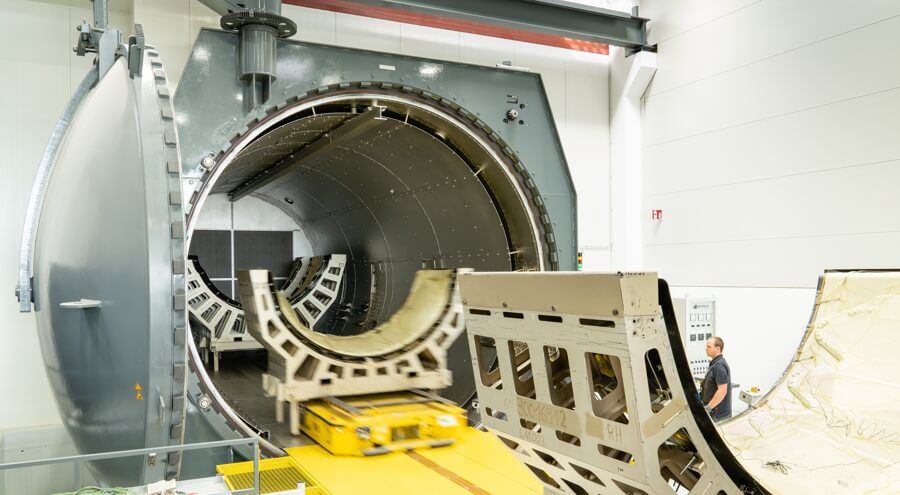

Space exploration has been one of the strongest drivers of technological development since its inception. The technical challenges it brings, from access to space to operation in a space environment, require new technical knowledge, innovation and initiatives in the development of new materials, manufacturing processes, the design of innovative structures, and the testing and evaluation of systems for space.