Air quality in aircraft cabins

18.06.2020

Modern commercial aircraft move at altitudes where human survival is not possible. Passengers are dependent on a self-sufficient, redundant pressure and air conditioning system in the aircraft. So-called HEPA filters ensure clean cabin air.

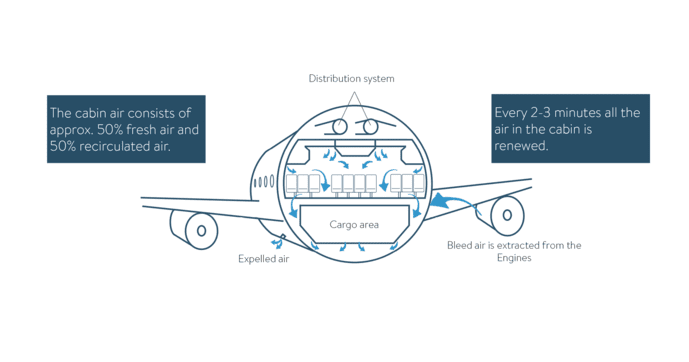

Cabin airflow

Fresh air, so-called bleed air, is taken directly from the compressor stages of the engines. The highly compressed, approx. 250° C hot air then enters the air-conditioning packs of the aircraft. There it is processed and fed into the cabin from above via distribution systems. The "old" air is sucked out downwards, so that an even circulation is created. The extracted air is either released into the external environment or returned through filters to the central air conditioning systems and fed back into the air cycle as recirculated air. All air in the cabin is renewed every 2-3 minutes, half of it by fresh and half by recirculated air.

Recirculated air

Recycled air is not fresh air and, given the large number of passengers, is contaminated by particles (fibres, dust or skin particles), bacteria, viruses and other micro-organisms and odours. All these contaminations pose a potential risk to passengers. Compared to bacteria, viruses thrive even at low humidity.

Cabin Infectiousness in an aircraft cabin

Of particular importance is the question of the extent to which passengers are at risk of infection from bacteria or viruses in the cabin air. Passengers repeatedly express the fear that there is a high risk of infection or contagion in aircraft cabins. However, knowing the technical equipment of the aircraft, this danger can be largely negated.

Modern filtration methods

Filtration methods were developed to protect the health of passengers. The recirculation air is constantly passed through highly efficient HEPA filters (High Efficiency Particulate Air Filters), which have the ability to remove particles with a size of 0.1 μm

| Particle type | Diameter (μm) | Typically associated disease |

| Human hair | approx. 30 - 50 | |

| Erythrocytes | approx. 8,0 | |

| Pneumococci | 0,5 | Pneumonia |

| Mycobacteria | 0,2 bis 1,0 | Tuberculosis |

| Influenza | 0,1 | Flu, pneumonia |

| Coronavirus | 0,16 | Disease courses are unspecific, diverse and vary widely, from symptomless courses to severe pneumonia with lung failure and death. |

Functionality of the filters

The filtering process is determined by the following three mechanisms:

- Direct interception: Filters consist of matrices with a precisely defined pore size. Like a sieve, particles larger than these pores are trapped directly on the surface of the filter system.

- Diffusional interception: Very small particles like viruses can pass through the empty spaces of filters. However, they are influenced by the "Brownian motion". The zigzag motion of the microscopic particles increases the probability of them colliding with a fiber of a filter element. The "Brownian motion" thus causes even the smallest particles to adhere to the fibres or pore walls. Particles with a size of about 0.1 μm (=1/10,000 millimetres) are detected with this principle.

- Inertial effect: Particles that have a higher density than air deviate from the actual air flow and settle on the surfaces and walls of the filters. This principle works best for particles ranging in size from 0.3 to 10 μm.

HEPA filters have the ability to filter out up to 99.9 percent of all particles in the cabin air and are replaced at regular intervals.

High efficiency particulate filter

The HEPA filters used in the aerospace industry are made of micro glass fibres, which are also used in hospitals. In this context, HEPA filters are also used to remove particles and aerosols.

Number of recirculation air filters per aircraft type

The number of filters available in a commercial aircraft to filter the recirculated air depends on the aircraft type (see table below).

| Aircraft type | Number of passengers | Number of filters |

| Airbus A300-600/A310 | 298/247 | 3 |

| Airbus A318/A319/A320/A321 | 117/134/164/199 | 2 |

| Airbus A330/A340 | from 293 for A330-200 to 419 for A340-600 | 4 resp. 8 |

| Boeing 737 -300, -500, -600, -700 | up to 149 | 1 |

| Boeing 737 -400, -800, -900 | up to 189 | 2 |

| Boeing 747-400 | up to 524 (2 Klassen) | 10 |

| Boeing 757 | 228 for -200 280 for -300 | 2 |

| Boeing 767 | up to 375 | 2 |

| Boeing 777 | up to 550 | 8 |

| DC-10/MD-11 | up to 410 | 1 |