Spoilers - Future in Motion

20.03.2017

When it comes to spoiler expertise, FACC strives to be number 1. A crucial factor for achieving this goal is research and development. Optimizing weight and manufacturing components efficiently are key parameters in this endeavor.

As part of its DAEDALUS R&D project, FACC is developing concepts for monolithic control surfaces in collaboration with the Johannes Kepler University Linz. ‘Monolithic‘ means that the spoilers are entirely composed of carbon-fiber reinforced polymer (CFRP). The aim is to save costs in comparison to sandwich designs featuring honeycomb cores.

State-of-the-art methods.

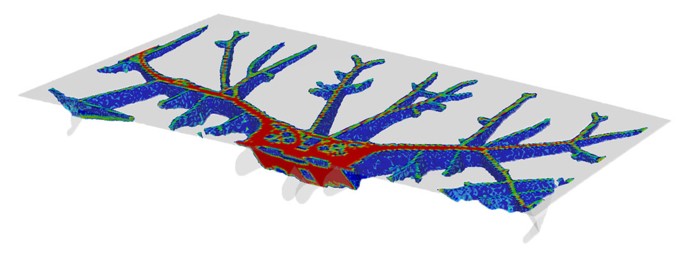

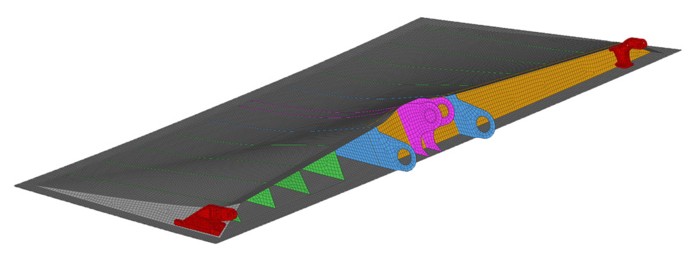

The required structures are being designed using computer- assisted optimization processes, with topology optimization providing structural design proposals through calculation. However, it‘s not just the shape that plays a major part; it‘s also the material, i.e. the laminate structure involved. Cutting-edge laminate optimization technology as well as lots of experience have been employed to determine the optimum number, alignment and thickness of the CFRP layers.

Two concepts.

Two concepts have been developed. The first concept features an aerodynamic skin (upper skin) glued to a reinforcing support structure (backbone, see Fig. above) consisting of integrated omega profiles. This geometrically sophisticated support is made of dry fiber material, soaked with epoxy resin and cured under vacuum conditions using the MARI process patented by FACC. Apart from the use of less expensive materials, the main advantage of the MARI process is that no additional pressure is needed for curing the composites in the oven.

The second concept is based on a traditional box design. What‘s so special about it is the integration of the upper and lower skin with the ribs to form a single CFRP component reinforced by means of a C profile on its front edge.

In addition to the two concepts of the DAEDALUS Project, FACC is investigating further innovative approaches such as spoilers with foam cores (see Take off 1/2016). All of these R&D paths, however, serve only one goal - to find the best solution for every conceivable spoiler requirement and size.