A network for the future

21.06.2017

FACC Research and Development

FACC's research and development staff has more than 500 employees. Additionally, our company maintains a strong cooperation network including universities and specialized institutions as well as customers. As tomorrow's mobility will be largely airborne, driving aerospace progress vigorously is a decisive factor.

THE HOLISTIC FACC APPROACH

Offering customers lighter, more efficient, more profitable, safer and more eco-friendly solutions is our aspiration. These goals are best achieved by synergies generated by research in a large variety of fields. Accordingly, FACC's efforts in this respect are very broad-based, ranging from the development of new materials and manufacturing processes to production optimization.

MOTIVATION.

Worldwide mobility and hence also passenger aviation are bound to in-crease. In the same way, however, requirements regarding environmental responsibility and climate protection are on the rise, not to mention fuel and energy costs. All these trends demand new solutions, and FACC is a partner for the global aviation industry driving innovation in this respect as well.

FUTURE ON BOARD.

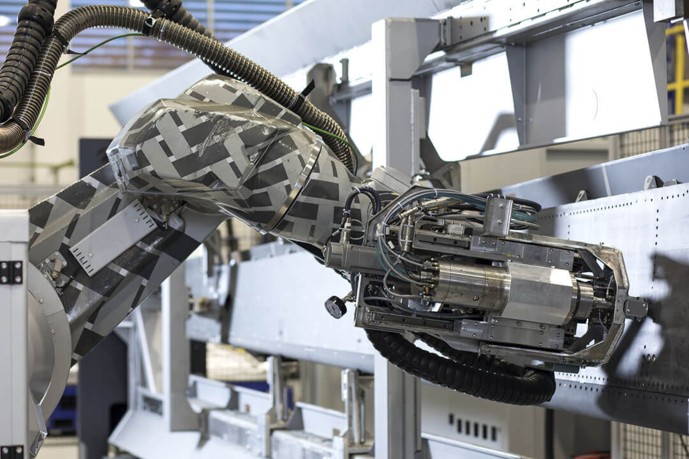

One example for FACC's fields of R&D are morphing sur faces. These are movable control surfaces integrated directly into components such as winglets or wings without any aero-dynamically disadvantageous flaps. Another key area of research is life cycle monitoring where primary struc-tures are able to monitor themselves by means of sensors supplying all the relevant data on component status even during flights and thus increa-sing overall safety. Thanks to life cycle monitoring, optimizations can be implemented and maintenance or repairs performed earlier and more cost-efficiently. Non-de-structive component testing based on thermographic imaging, a process developed by FACC, has already proved itself in practice. This invention saves time and costs and guarantees a new dimension of accuracy.

COOPERATION WITH CUSTOMERS.

FACC is a partner of global market leaders providing powerful solutions, especially when it comes to specific, application-oriented projects. Ex-amples for this role include the de-velopment and implementation of innovative overhead stowage compartment designs for Airbus or FACC's collaboration with Boeing in developing composite seat shells for economy class seating.

COOPERATION WITH SCIENCE AND INDUSTRIAL PRACTICE.

In the dynamic field of lightweight construction, new insights are gained on a daily basis. Thanks to its superior connections in the realm of science, FACC is always ahead of the curve and thus enjoys a decisive competitive edge. These connections include uni-versities of technology, technological colleges and competence centers as well as many project-oriented part-nerships on both a national and inter-national level. FACC's commitment in numerous areas beyond the confines of the aviation industry was validated yet again when FACC CEO Robert Machtlinger was recently elected spokesperson of the Austrian Advan-ced Lightweight Technology platform. This platform is made up of a network of nearly 30 companies including representatives from the automotive and aircraft industries as well as from the fields of plastics and mechatro-nics working on innovative projects and developing new approaches to lightweight design applications using state-of-the-art materials.

COOPERATION WITH ACADEMIA.

Training future professionals in line with practice-oriented requirements is a major ambition of our company. One example is a professorship in the field of aircraft systems at the Vienna University of Technology recently established with the help of FACC. Another illustration for this claim is our cooperation with the University of Ap-plied Sciences in Wels near the FACC plants in Upper Austria where FACC initiated a Lightweight Construction and Composite Materials study pro-gram and even offers internships for the solution finders of tomorrow.