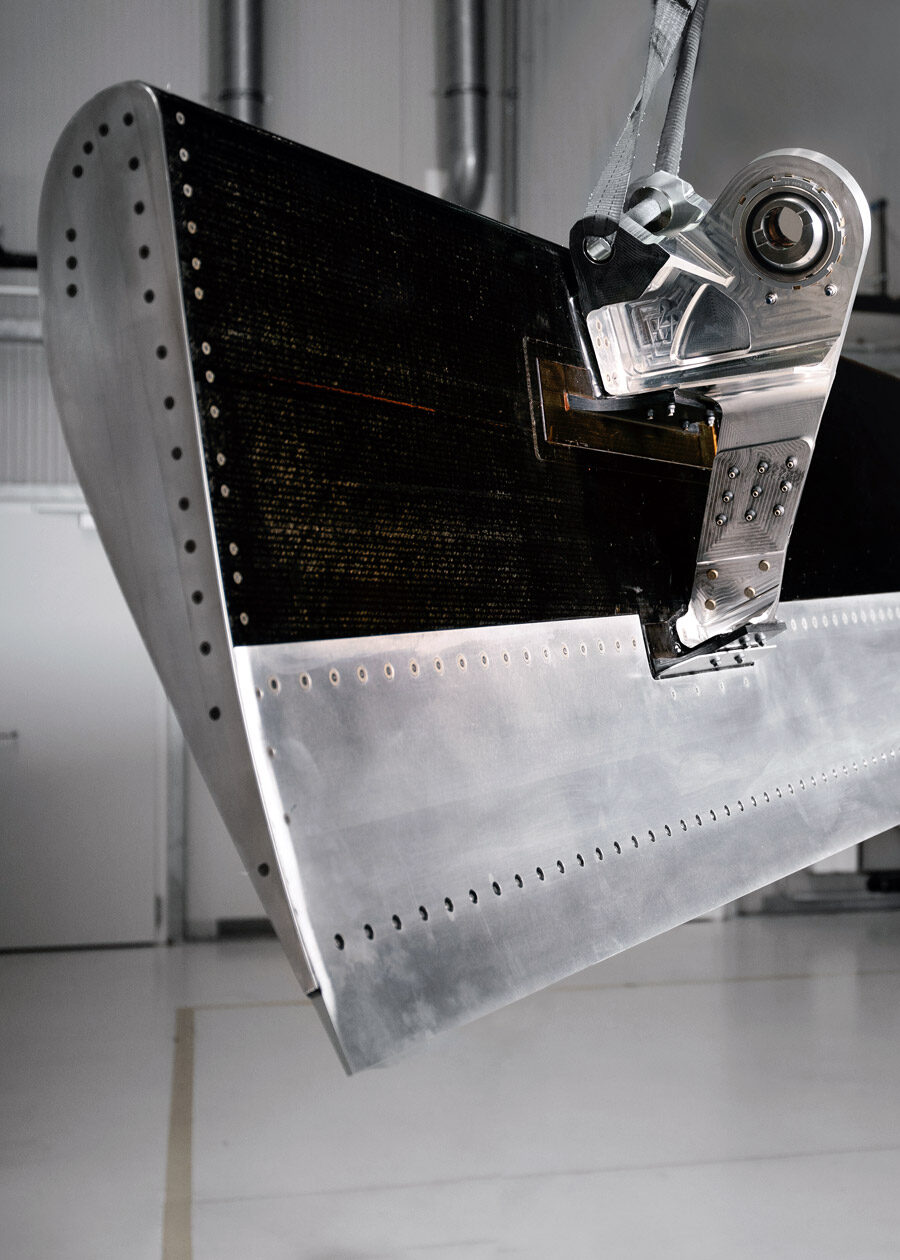

We are designing, producing, and maintaining aerostructures for passenger aircraft and executive jets, including primary structures like rudders and elevators. Our advanced lightweight systems are enhancing aerodynamics, reducing take-off weight, and positively impacting fuel consumption.

Aerostructures

Innovative, Lightweight & Durable

What we are doing

Aerostructures for

civil aviation

See our

current portfolio

Winglets & Wingtips

Winglets are designed to reduce the aerodynamic induced drag by reducing the pressure bleed from the high pressure, bottom surface of the wing to the low pressure, top surface of the wing. This reduces the energy lost by means of the tip vortex.

Flaps

Flaps are deployed downward on takeoff and landing to increase the amount of lift produced by the wing during slow flight. Flap deployment at the wing trailing edge is usually combined with Slat deployment during takeoff and landing which also increases Lift of the wing in slow fligth.

Spoilers

Spoilers, also known as air brakes, are movable panels on the upper side of aircraft wings. When extended, they reduce the lift of the wings and increase drag at the same time. This is used to decelerate the airplane and to induce decent. Some spoilers are also designed to participate in the aerodynamic shaping of the slow speed, high lift wing (with flaps deployed) using a droop function.

Ailerons

The ailerons are located at the trailing edge of the wing, far outboard. They work opposite to each other, so when one is raised, the other is lowered. Their function is to increase the lift on one wing, while reducing the lift on the other. By doing this, they roll the aircraft about the longitudinal axis, which allows the aircraft to turn when combined with rudder movements.

Vertical stabilizer and rudder

The Vertical stabilizer is a symmetrical vertical fin on the tail of the aircraft and keeps the airplane in stable directional motion without yawing. At the trailing edge of the vertical stabilizer sits the rudder. It can be deflected towards port or starboard which induces an intentionally yaw motion of the airplane. Together with the movement of the ailerons, the rudder deflection commands the airplane into a turn.

Horizontal Stabilizer and Elevators

The horizontal stabilizer is a horizontal fin on the tail of the aircraft. It Keeps the aircraft in stable level flight. The elevators are fixed to the trailing edge of the horizontal stabilizers. When deflected upwards or downwards the elevators can pitch the aircraft nose-up or nose-down respectively which commands the aircraft into a climb or decent.

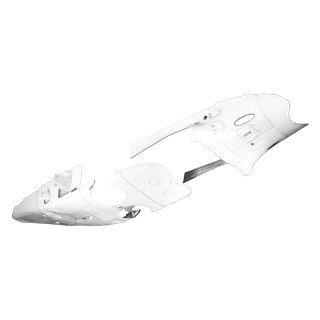

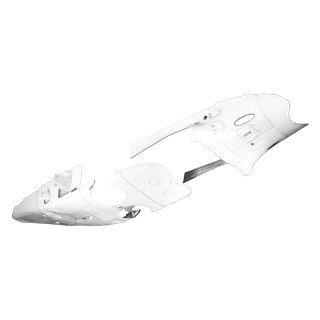

Wing to body fairings

Wing to body fairings form an aerodynamic envelope transition between the wing and the fuselage of an aircraft. These fairings also cover a number of aircraft systems that are intentionally installed outside of the pressurized fuselage.

Flap track fairings

The fairing covers and encases the guide rail and the drive system that retracts and extends the flaps. As the word suggests, this “fairing” gives the component a “fair”, i.e. smooth shape thereby minimizing the negative aerodynamic effect of the flap track and actuation system. Of course it also acts as a protective layer preventing dirt an debris to interfere with the system.

Radomes

The removable, round aircraft tip, which is permeable to electromagnetic radiation, is used to protect antennas. In the aircraft nose.

Winglets & Wingtips

Winglets are designed to reduce the aerodynamic induced drag by reducing the pressure bleed from the high pressure, bottom surface of the wing to the low pressure, top surface of the wing. This reduces the energy lost by means of the tip vortex.

Wing to body fairings

Wing to body fairings form an aerodynamic envelope transition between the wing and the fuselage of an aircraft. These fairings also cover a number of aircraft systems that are intentionally installed outside of the pressurized fuselage.

Global Customer Network

The Who’s Who is among our

long-standing customers

We are proud to be a preferred aerostructures technology partner for all leading global aircraft manufacturers.

Aviation Takes Off: 42,500 New Aircraft by 2043 – Net-Zero by 2050.

Innovating Aviation for a Sustainable Future

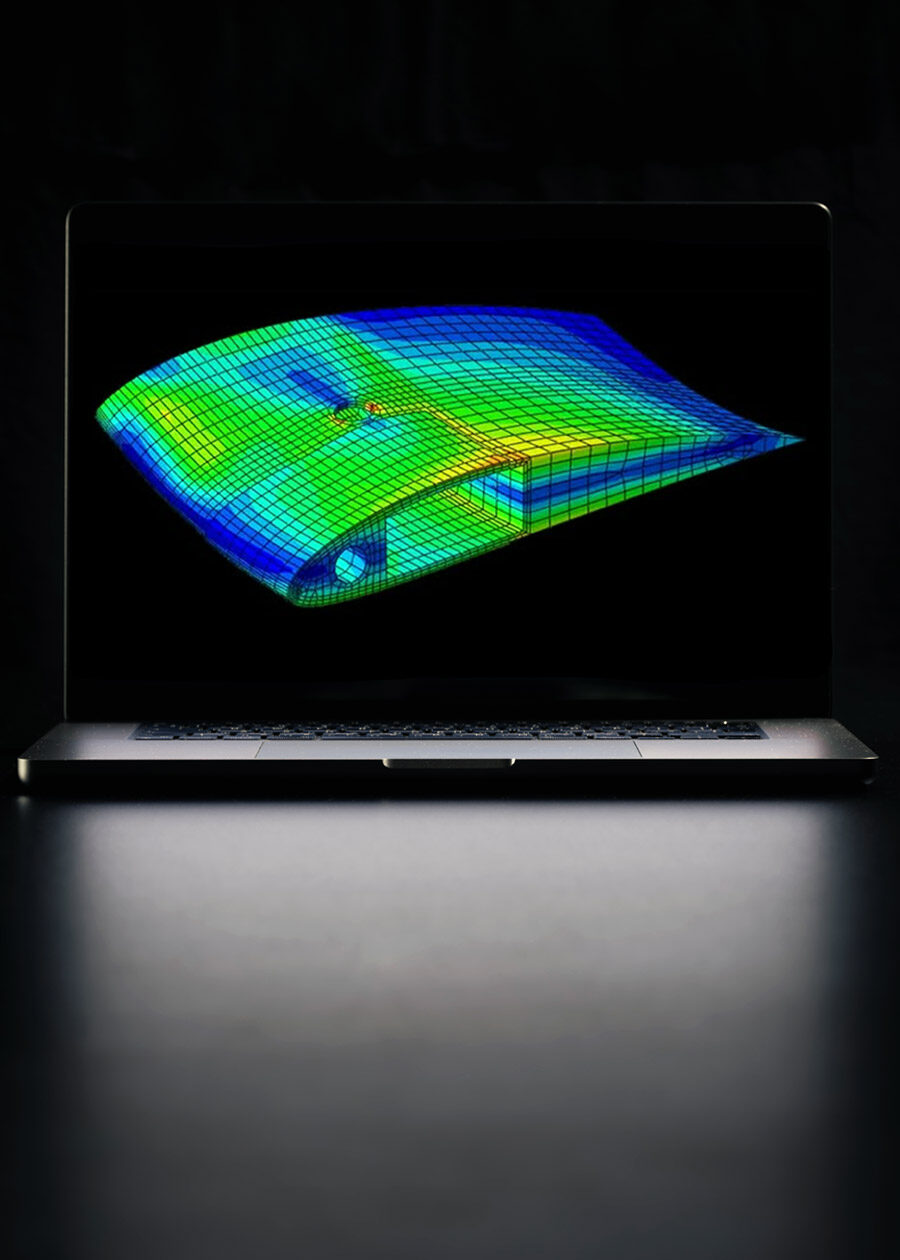

FACC tackles rising fuel costs, production demands, and sustainability goals with structural solutions that make aircraft components lighter, safer, and more efficient.

Automation

Thermoplastics

Thermoplastics

Thermosets