With over 35 years of experience and a steadfast commitment to continuous technological advancement, we are excelling in taking on cutting-edge projects. We are delivering turnkey solutions, from the conceptual phase to full-scale production and MRO (Maintenance, Repair, and Overhaul) services, turning brilliant ideas into commercial reality.

Turning brilliant ideas

into commercial reality

All you need from a tight knit team

Our certifications in design (Part 21/J), production (Part 21/G), and maintenance (Part 145) showcase our expertise in mastering technologies of any complexity. These certifications form the cornerstone of our ability to deliver tailored and innovative solutions to our customers throughout the entire product lifecycle.

We are authorized to design cabin and structures encompassing major modifications (STCs), major and minor repairs, as well as major and minor changes.

Thermoplastics

Thermosets

Bio-sourced resins

Design Engineering

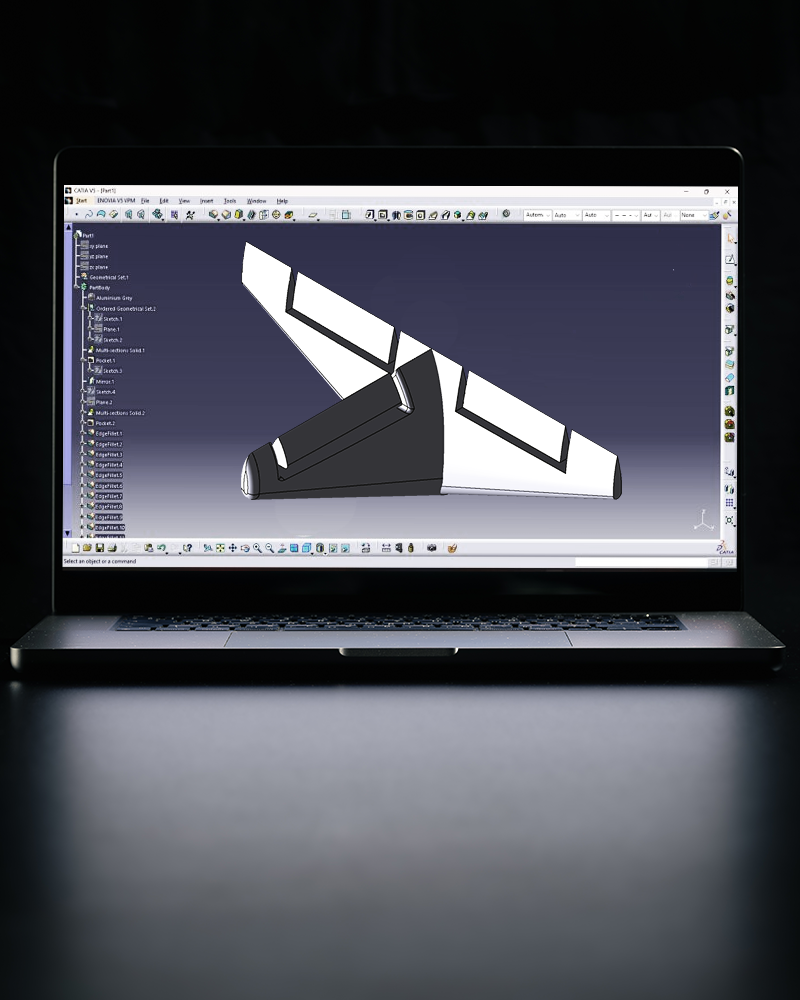

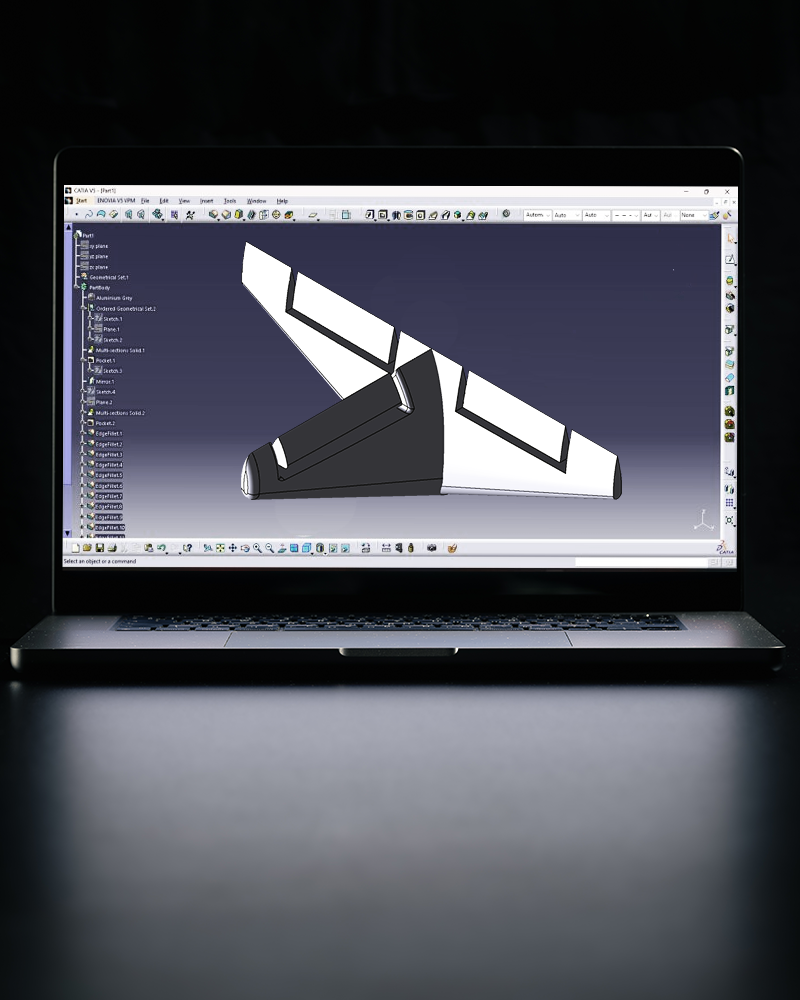

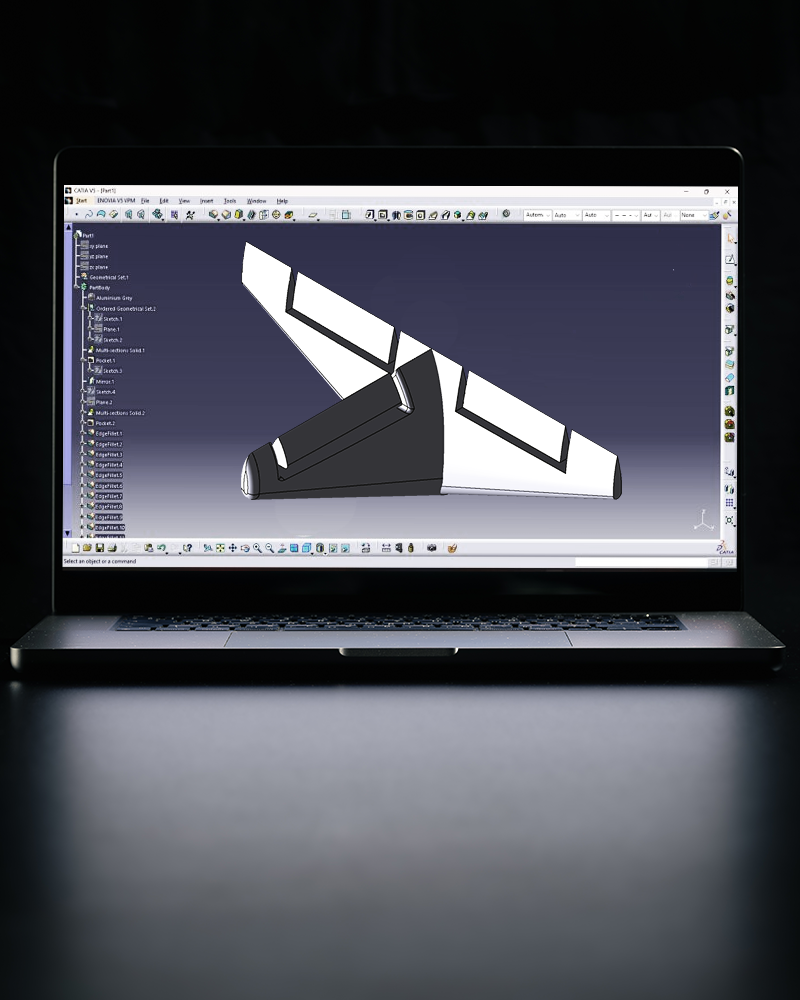

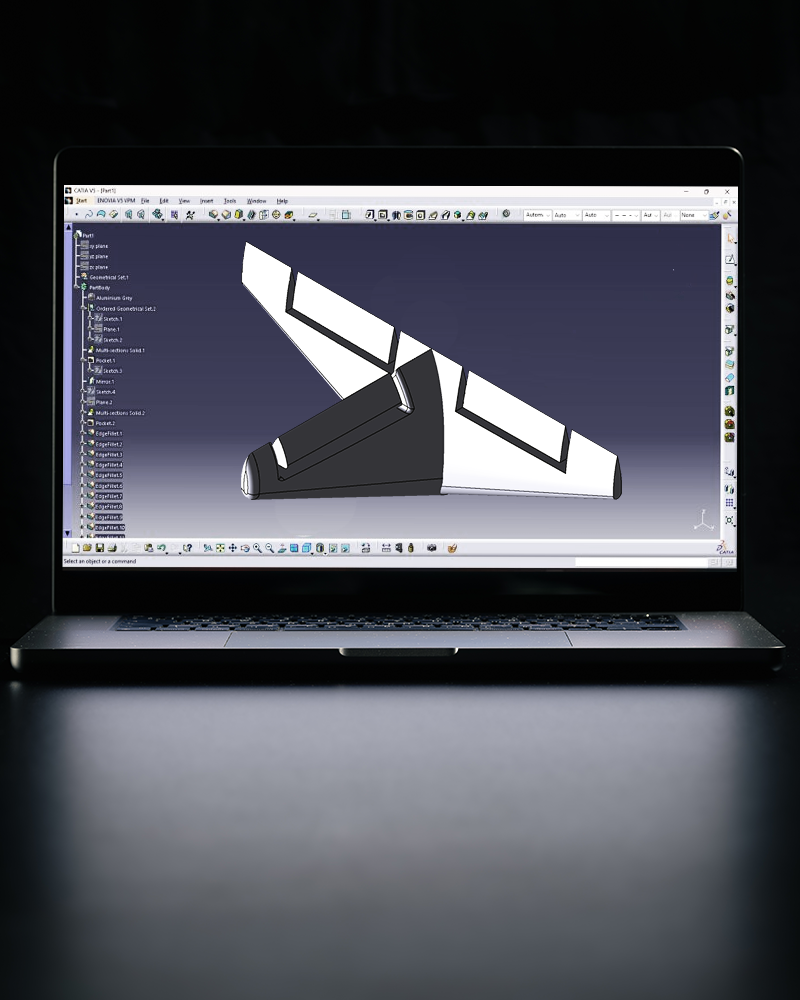

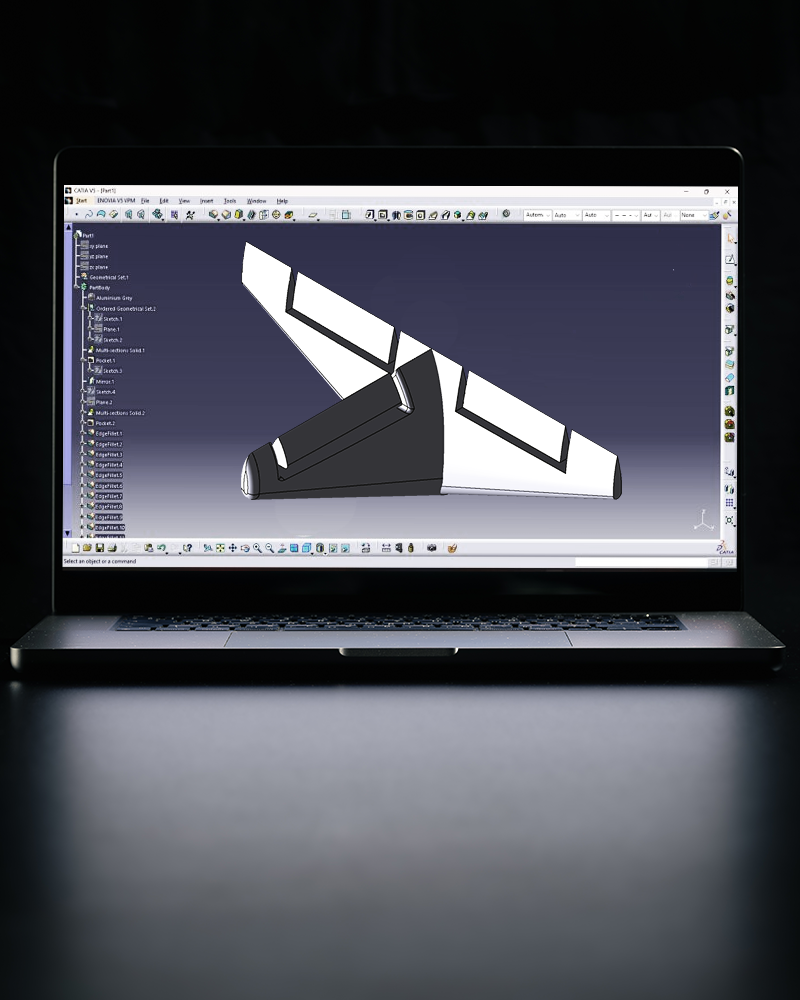

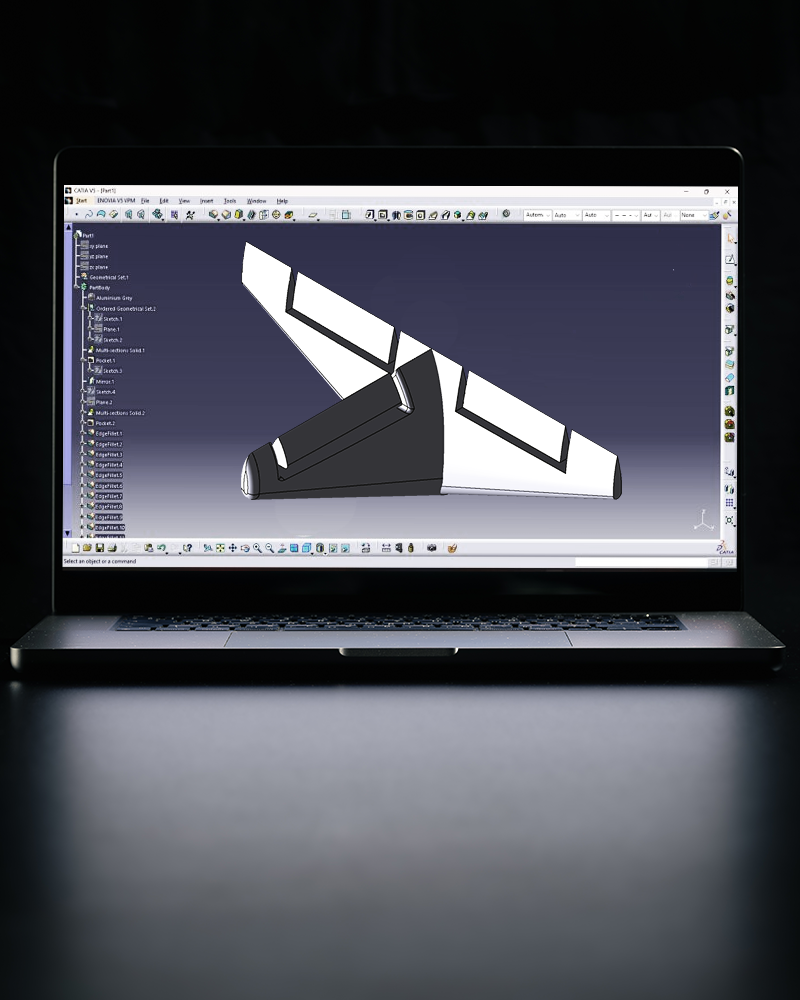

When it comes to designing lightweight components and systems, you can think of it as being about three E’s: Environment, Efficiency, and Economy. We’re supporting our customers from day one – from the first concept to a series-ready product, whether for small or large-scale production.

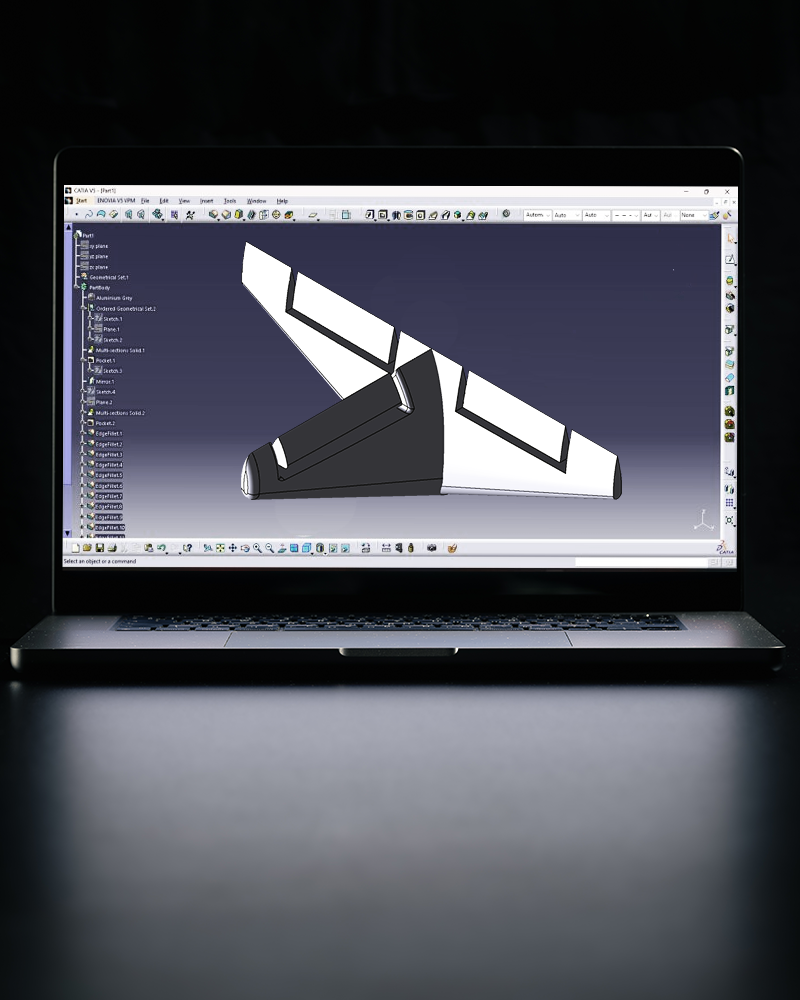

We’re engineering with purpose: from requirement-driven construction and weight-optimized design to complex tooling. Our expertise in composites, metals, and assembly design, paired with cutting-edge tools like CATIA V5, 3DX, and NX, and seamless data interfaces, is enabling us to collaborate efficiently and bring aerospace innovations to market faster.

Anlaysis engineering

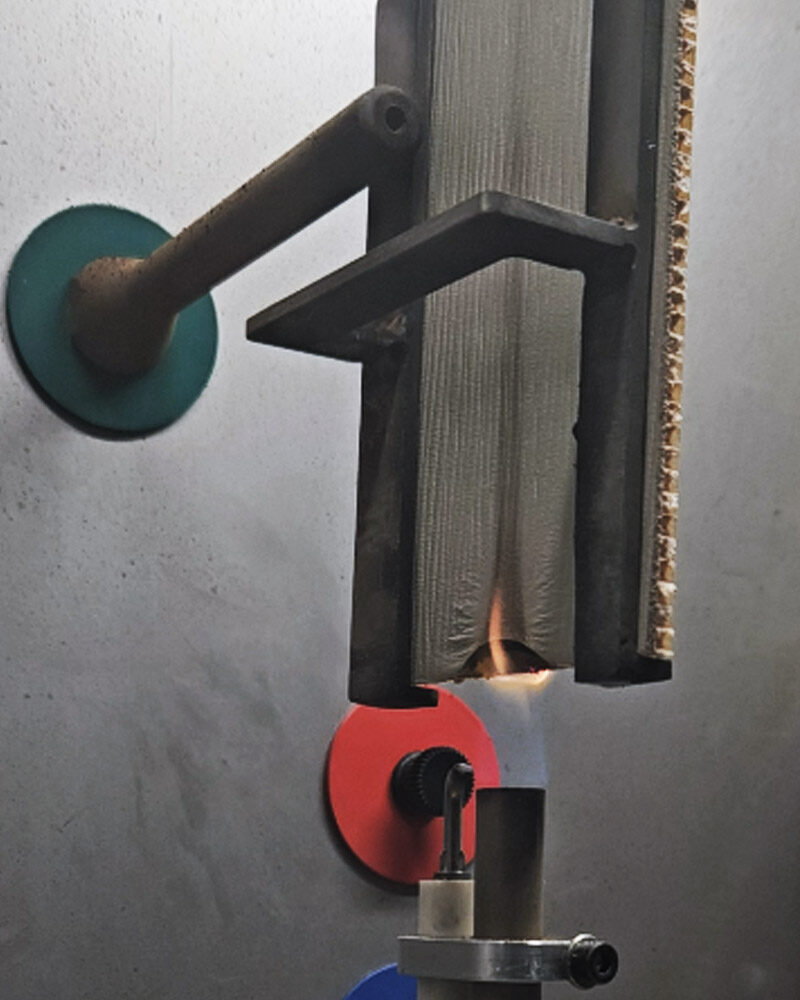

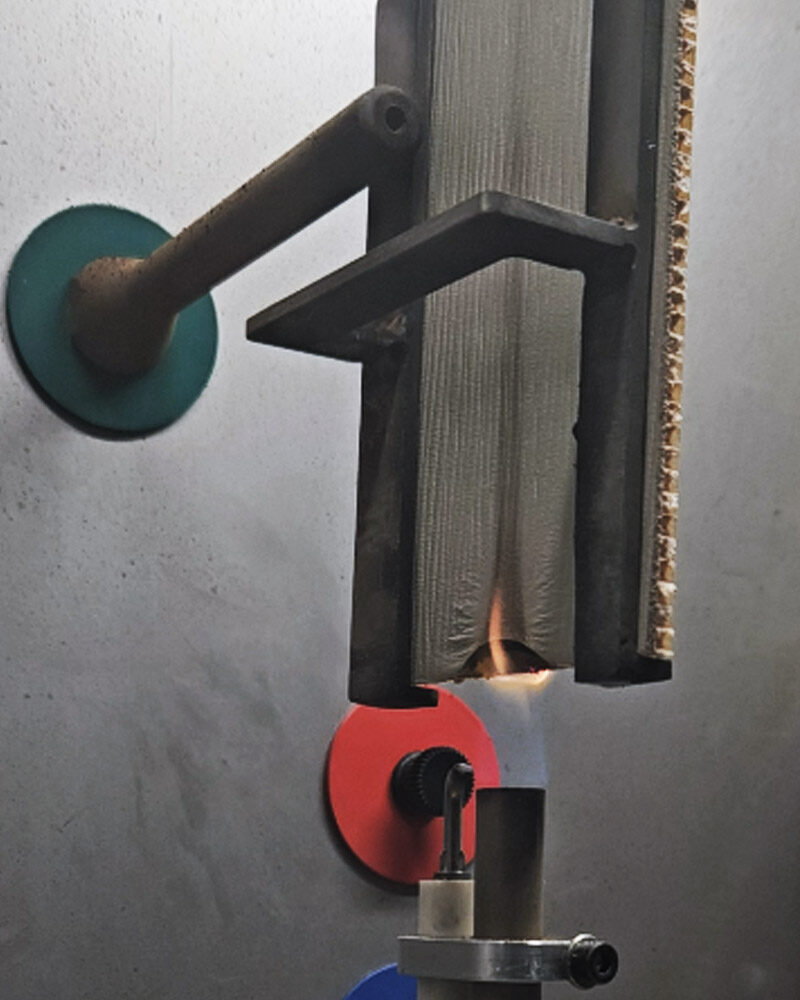

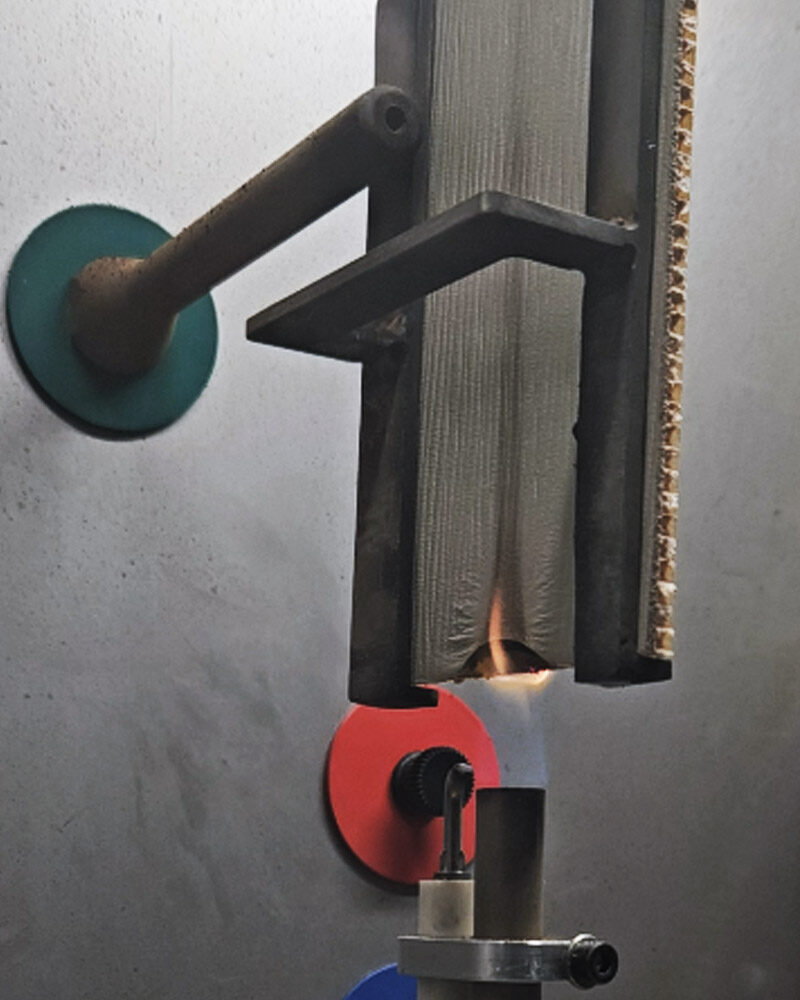

Additionally, we are developing and verifying allowable damage tolerances, predicting and post-processing test results, designing and validating repair concepts, and optimizing topology and layup configurations. Virtual testing and progressive failure analysis—including assembly processes and parameter calibration—are also part of our integrated service offering.

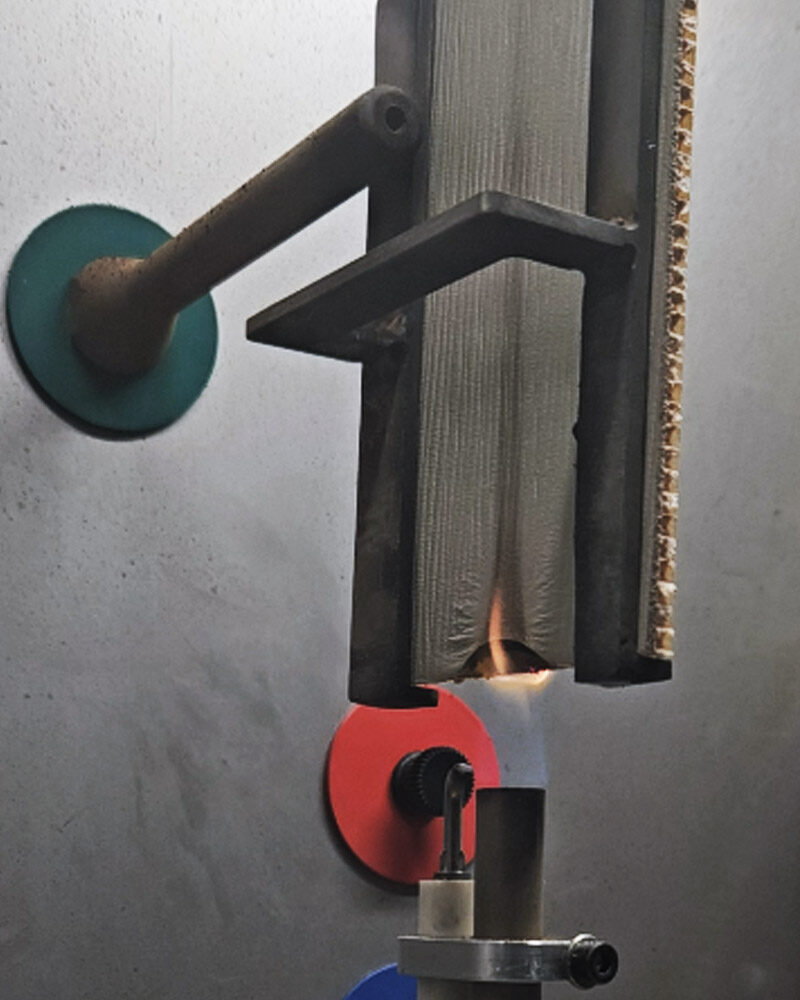

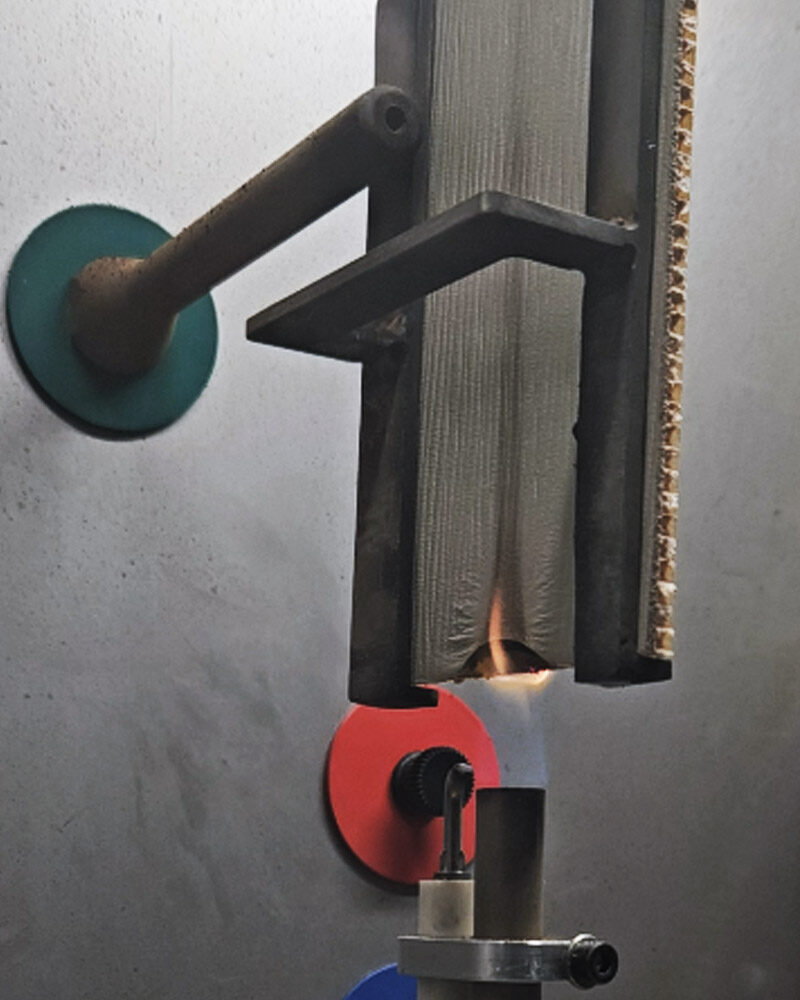

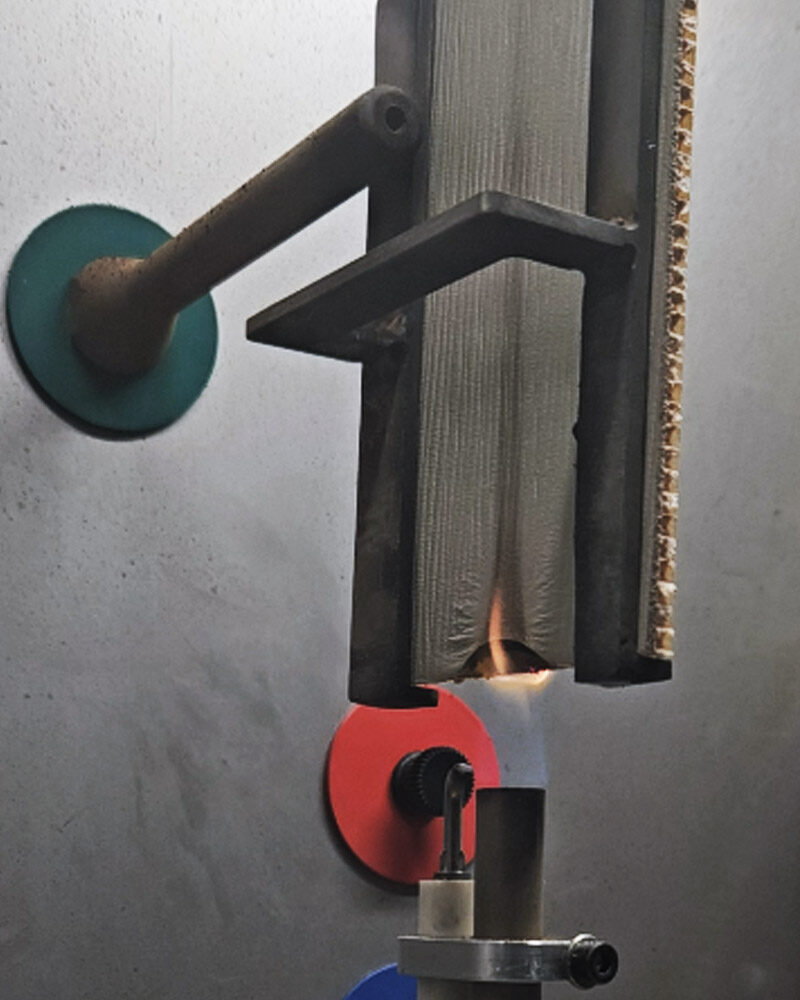

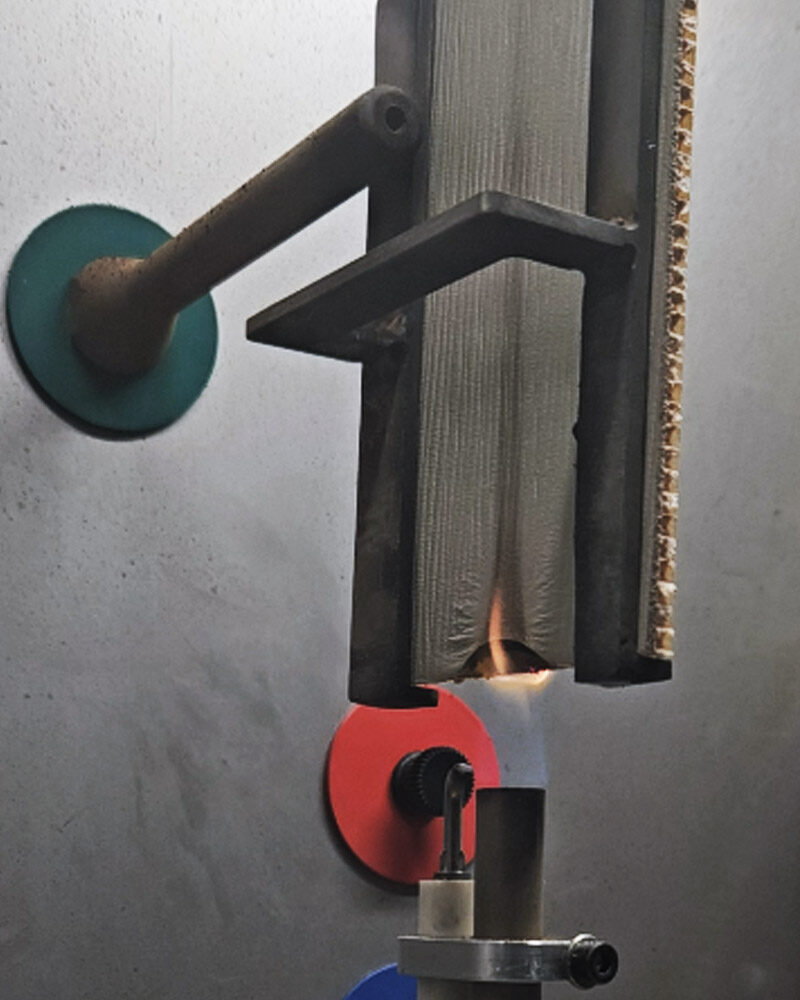

Certification & Testing

Qualification

Thermoplastics

Thermosets

Bio-sourced resins

Design Engineering

When it comes to designing lightweight components and systems, you can think of it as being about three E’s: Environment, Efficiency, and Economy. We’re supporting our customers from day one – from the first concept to a series-ready product, whether for small or large-scale production.

We’re engineering with purpose: from requirement-driven construction and weight-optimized design to complex tooling. Our expertise in composites, metals, and assembly design, paired with cutting-edge tools like CATIA V5, 3DX, and NX, and seamless data interfaces, is enabling us to collaborate efficiently and bring aerospace innovations to market faster.

Anlaysis engineering

Additionally, we are developing and verifying allowable damage tolerances, predicting and post-processing test results, designing and validating repair concepts, and optimizing topology and layup configurations. Virtual testing and progressive failure analysis—including assembly processes and parameter calibration—are also part of our integrated service offering.

Certification & Testing

Qualification

Thermoplastics

Thermosets

Bio-sourced resins

Design Engineering

When it comes to designing lightweight components and systems, you can think of it as being about three E’s: Environment, Efficiency, and Economy. We’re supporting our customers from day one – from the first concept to a series-ready product, whether for small or large-scale production.

We’re engineering with purpose: from requirement-driven construction and weight-optimized design to complex tooling. Our expertise in composites, metals, and assembly design, paired with cutting-edge tools like CATIA V5, 3DX, and NX, and seamless data interfaces, is enabling us to collaborate efficiently and bring aerospace innovations to market faster.

Anlaysis engineering

Additionally, we are developing and verifying allowable damage tolerances, predicting and post-processing test results, designing and validating repair concepts, and optimizing topology and layup configurations. Virtual testing and progressive failure analysis—including assembly processes and parameter calibration—are also part of our integrated service offering.

Certification & Testing

Qualification

Thermoplastics

Thermosets

Bio-sourced resins

Design Engineering

When it comes to designing lightweight components and systems, you can think of it as being about three E’s: Environment, Efficiency, and Economy. We’re supporting our customers from day one – from the first concept to a series-ready product, whether for small or large-scale production.

We’re engineering with purpose: from requirement-driven construction and weight-optimized design to complex tooling. Our expertise in composites, metals, and assembly design, paired with cutting-edge tools like CATIA V5, 3DX, and NX, and seamless data interfaces, is enabling us to collaborate efficiently and bring aerospace innovations to market faster.

Anlaysis engineering

Additionally, we are developing and verifying allowable damage tolerances, predicting and post-processing test results, designing and validating repair concepts, and optimizing topology and layup configurations. Virtual testing and progressive failure analysis—including assembly processes and parameter calibration—are also part of our integrated service offering.

Certification & Testing

Qualification

Thermoplastics

Thermosets

Bio-sourced resins

Design Engineering

When it comes to designing lightweight components and systems, you can think of it as being about three E’s: Environment, Efficiency, and Economy. We’re supporting our customers from day one – from the first concept to a series-ready product, whether for small or large-scale production.

We’re engineering with purpose: from requirement-driven construction and weight-optimized design to complex tooling. Our expertise in composites, metals, and assembly design, paired with cutting-edge tools like CATIA V5, 3DX, and NX, and seamless data interfaces, is enabling us to collaborate efficiently and bring aerospace innovations to market faster.

Anlaysis engineering

Additionally, we are developing and verifying allowable damage tolerances, predicting and post-processing test results, designing and validating repair concepts, and optimizing topology and layup configurations. Virtual testing and progressive failure analysis—including assembly processes and parameter calibration—are also part of our integrated service offering.

Certification & Testing

Qualification

Thermoplastics

Thermosets

Bio-sourced resins

Design Engineering

When it comes to designing lightweight components and systems, you can think of it as being about three E’s: Environment, Efficiency, and Economy. We’re supporting our customers from day one – from the first concept to a series-ready product, whether for small or large-scale production.

We’re engineering with purpose: from requirement-driven construction and weight-optimized design to complex tooling. Our expertise in composites, metals, and assembly design, paired with cutting-edge tools like CATIA V5, 3DX, and NX, and seamless data interfaces, is enabling us to collaborate efficiently and bring aerospace innovations to market faster.

Anlaysis engineering

Additionally, we are developing and verifying allowable damage tolerances, predicting and post-processing test results, designing and validating repair concepts, and optimizing topology and layup configurations. Virtual testing and progressive failure analysis—including assembly processes and parameter calibration—are also part of our integrated service offering.

Certification & Testing

Qualification

Thermoplastics

Thermosets

Bio-sourced resins

Design Engineering

When it comes to designing lightweight components and systems, you can think of it as being about three E’s: Environment, Efficiency, and Economy. We’re supporting our customers from day one – from the first concept to a series-ready product, whether for small or large-scale production.

We’re engineering with purpose: from requirement-driven construction and weight-optimized design to complex tooling. Our expertise in composites, metals, and assembly design, paired with cutting-edge tools like CATIA V5, 3DX, and NX, and seamless data interfaces, is enabling us to collaborate efficiently and bring aerospace innovations to market faster.

Anlaysis engineering

Additionally, we are developing and verifying allowable damage tolerances, predicting and post-processing test results, designing and validating repair concepts, and optimizing topology and layup configurations. Virtual testing and progressive failure analysis—including assembly processes and parameter calibration—are also part of our integrated service offering.

Certification & Testing

Qualification

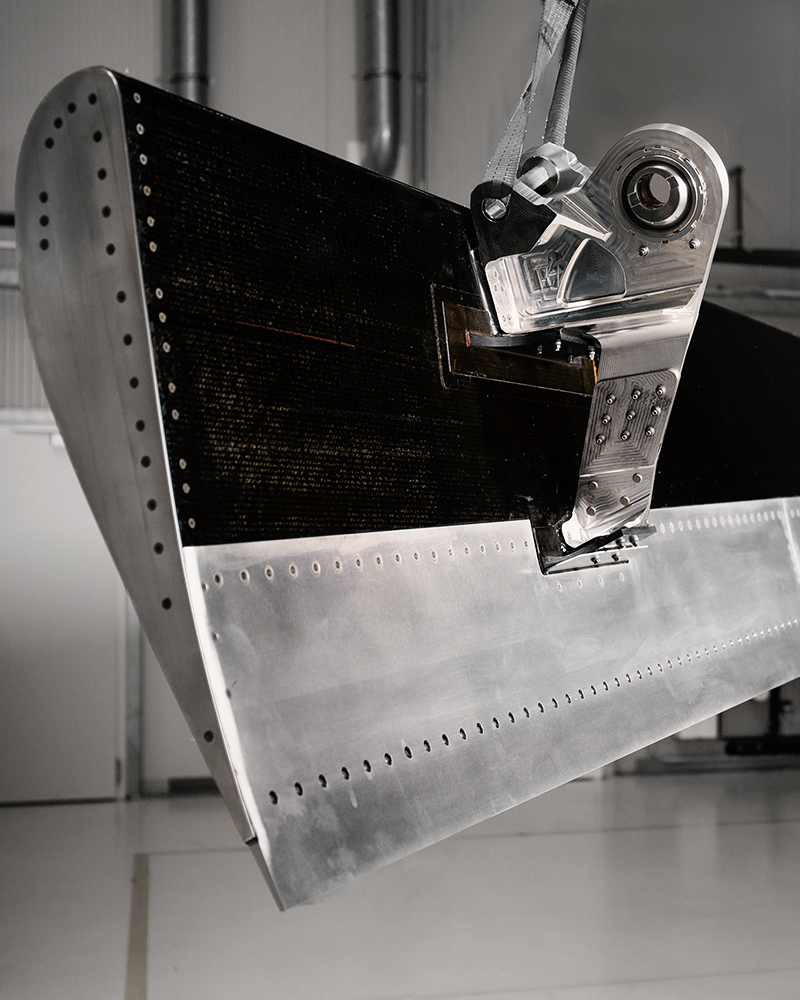

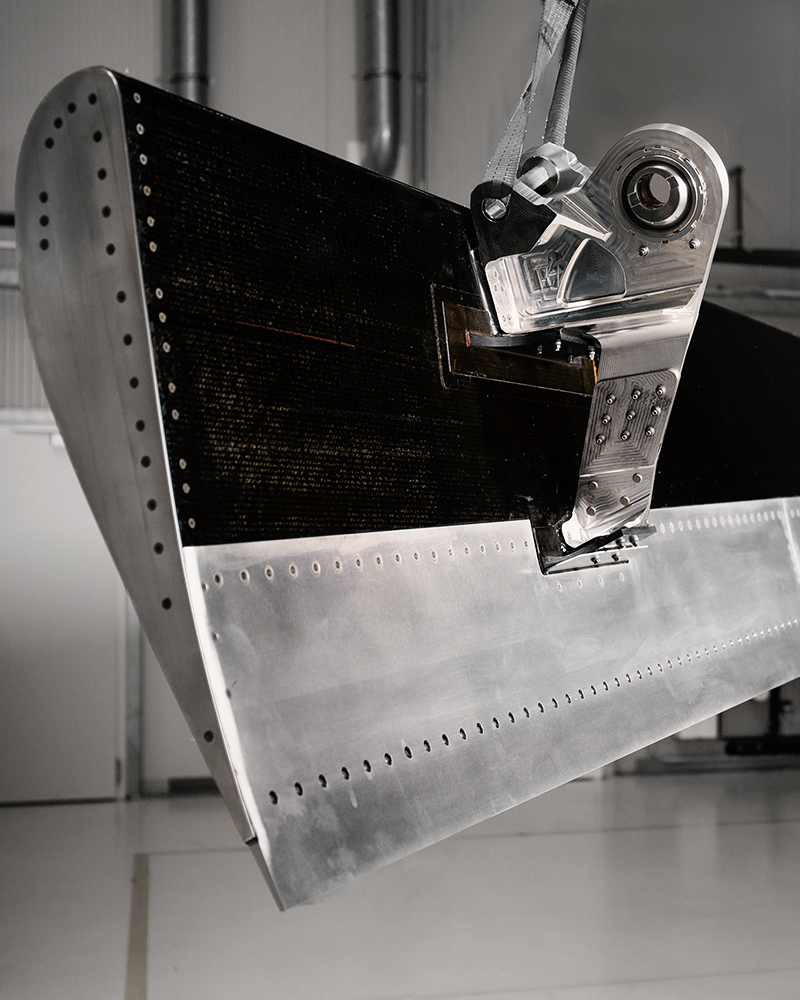

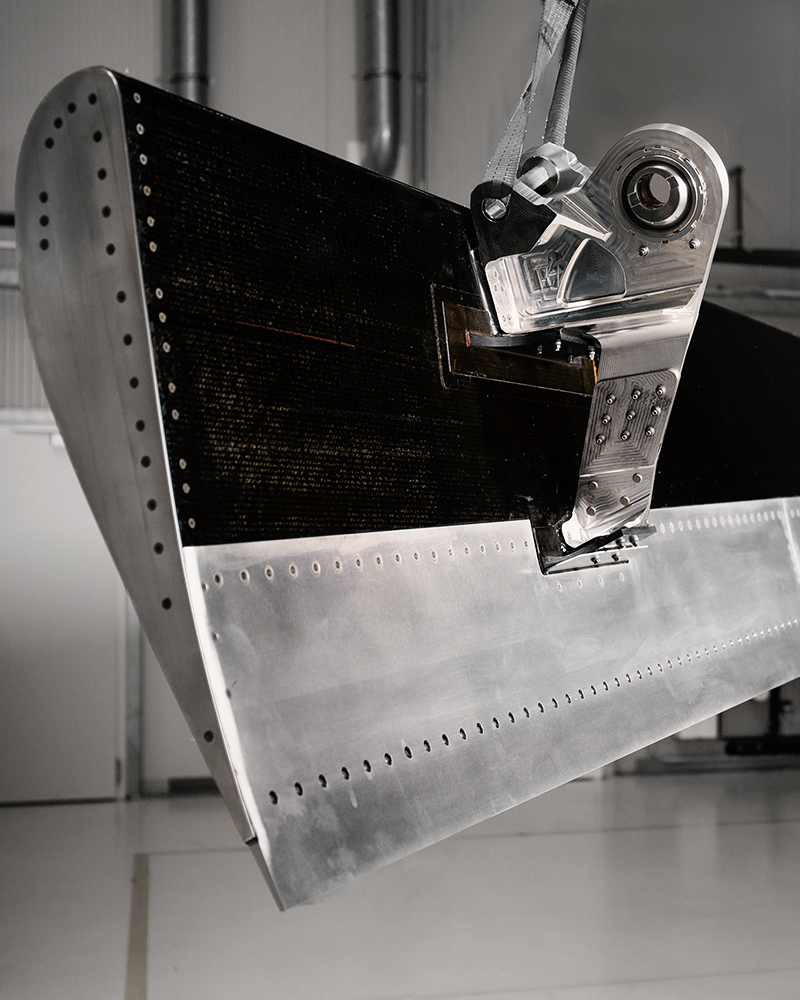

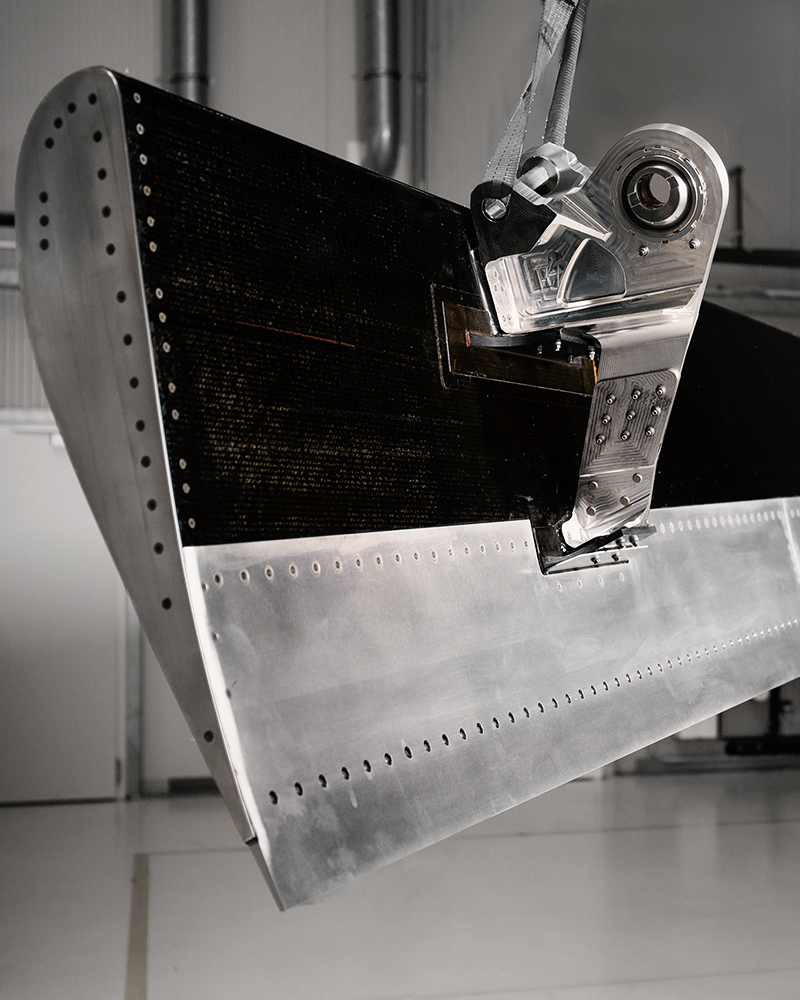

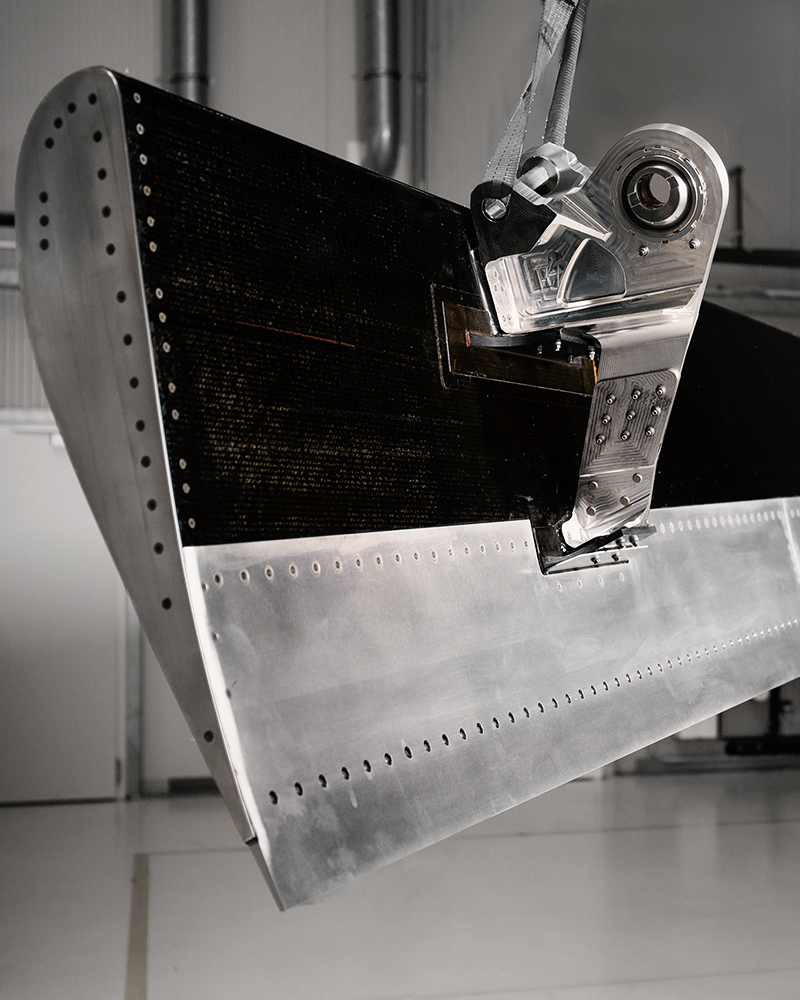

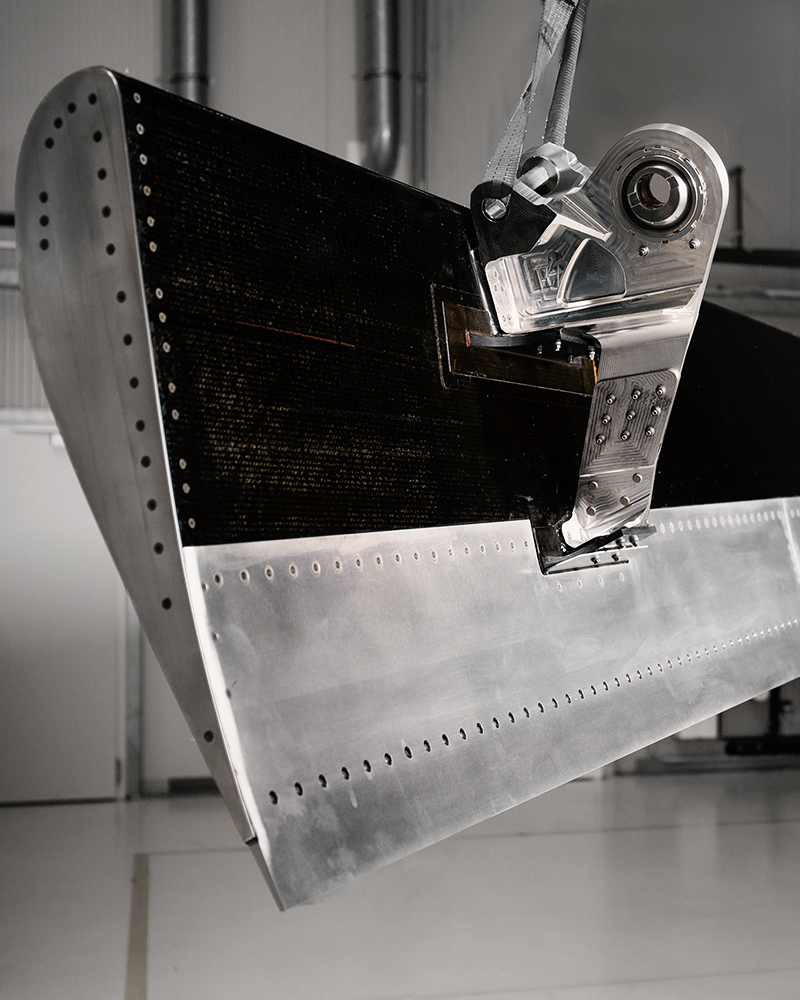

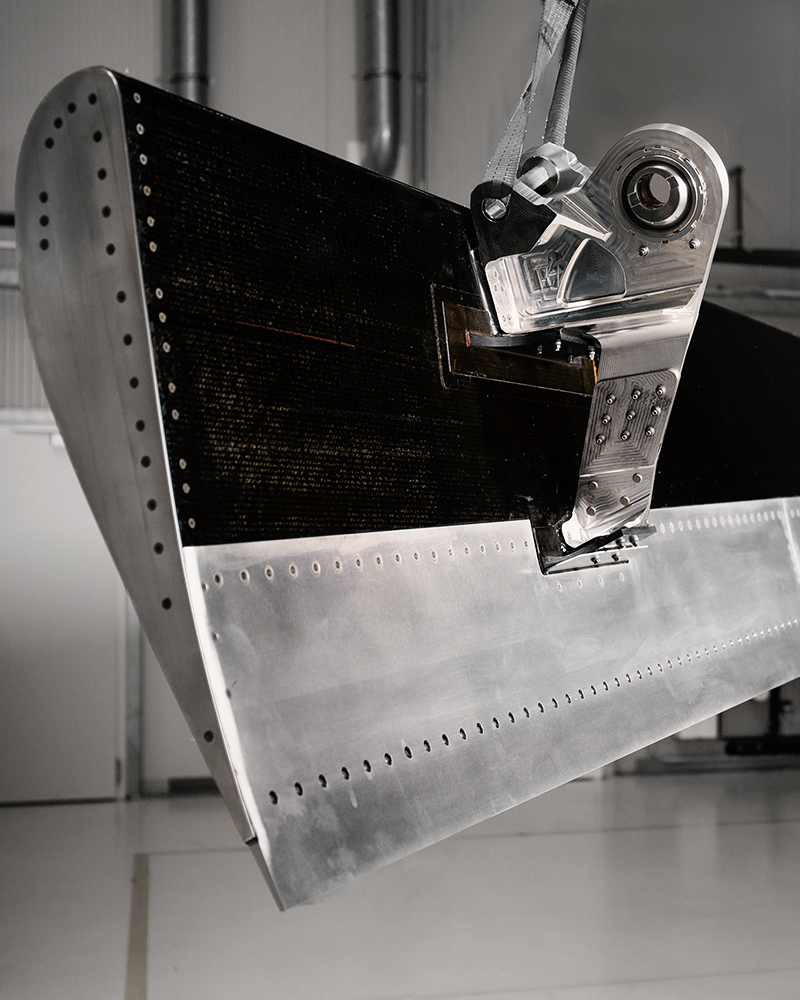

Whether for small or large series, we offer unique value in series —from passenger aircraft and executive jets to passenger and logistics drones. Our certified solutions in aircraft structures, engines and nacelles, and cabin interiors have proven reliable in fleets worldwide.

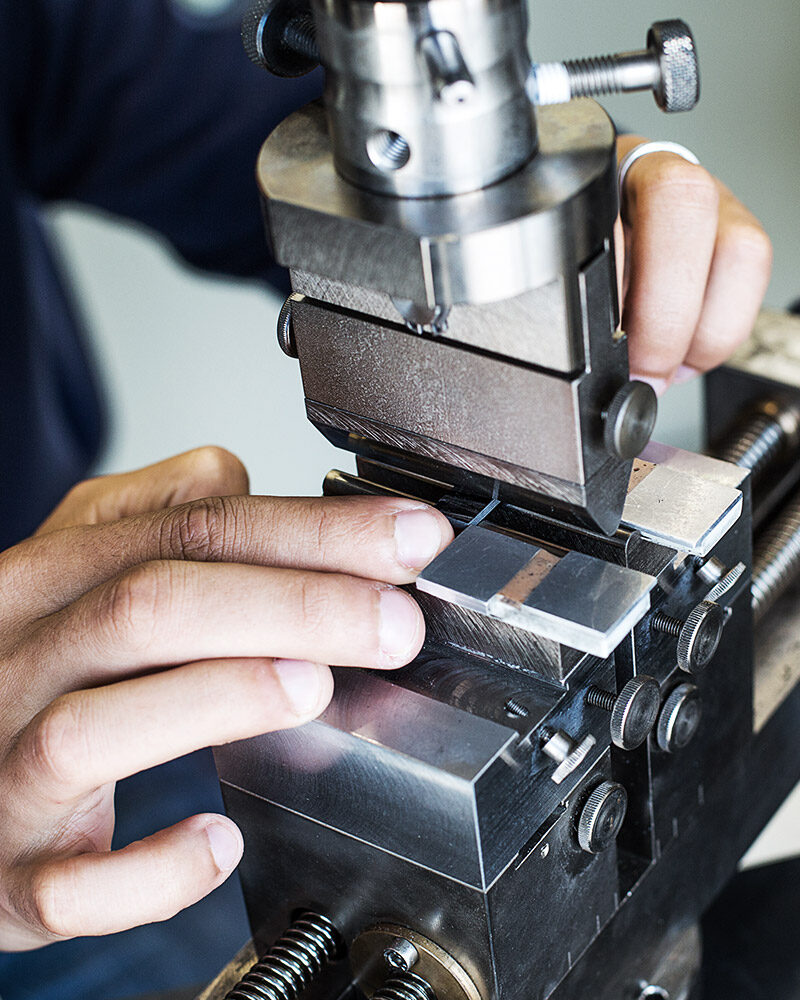

Industrialization

Tooling

Automated Tape Laying

Hot Drape Forming

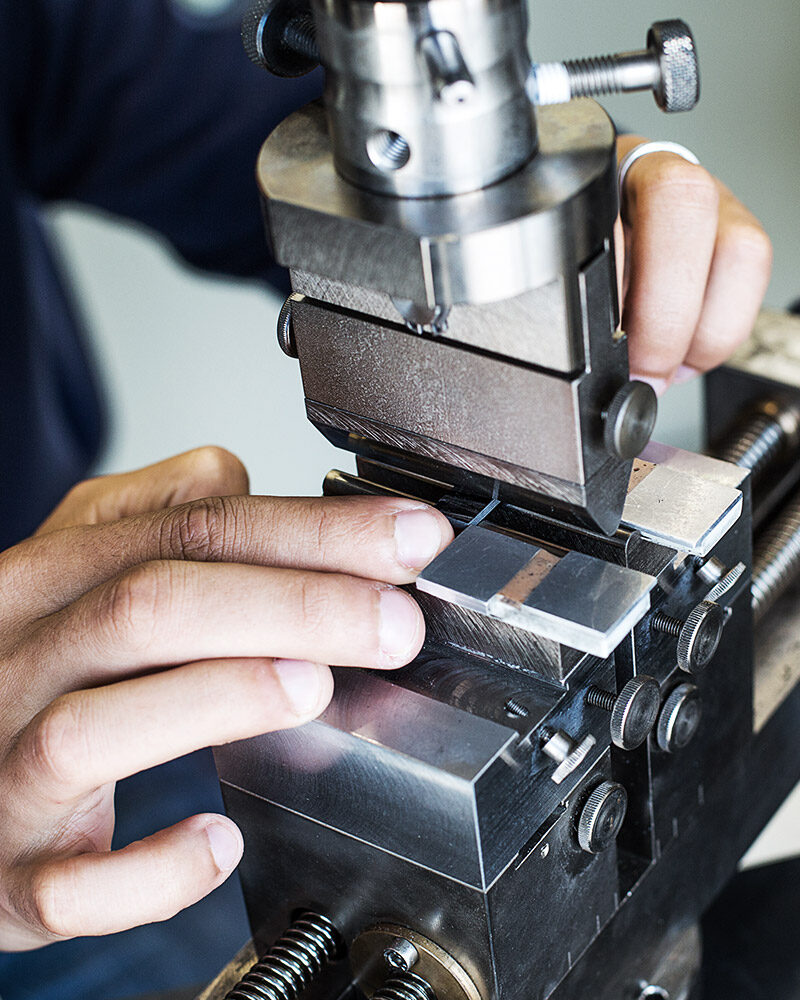

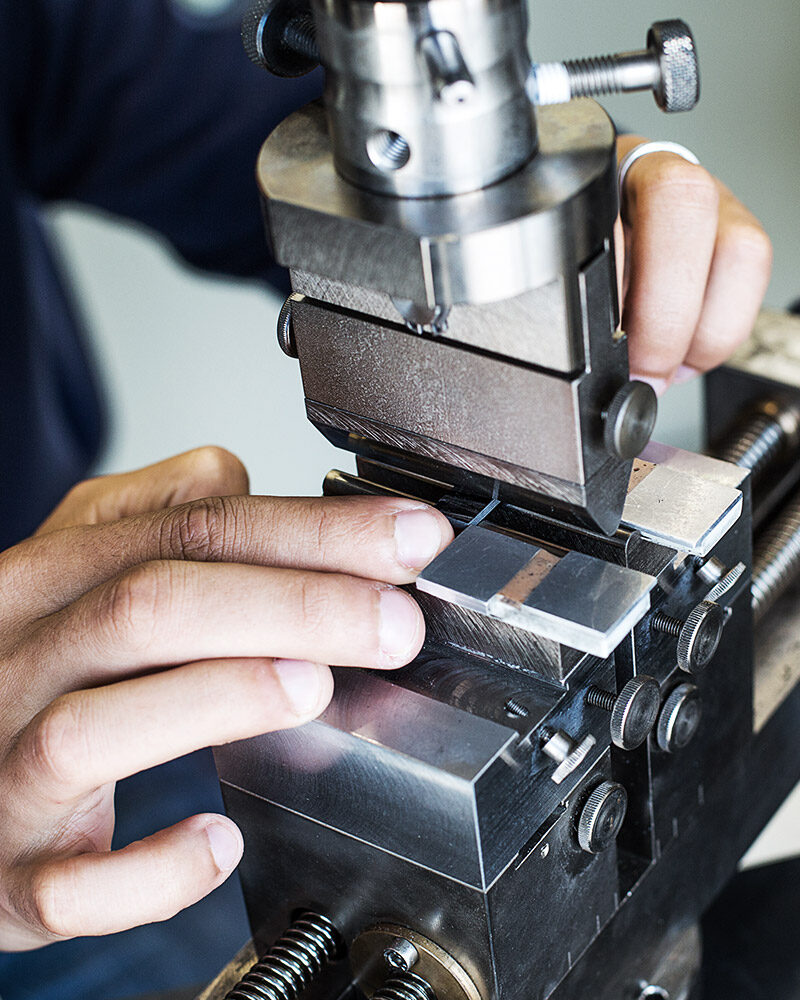

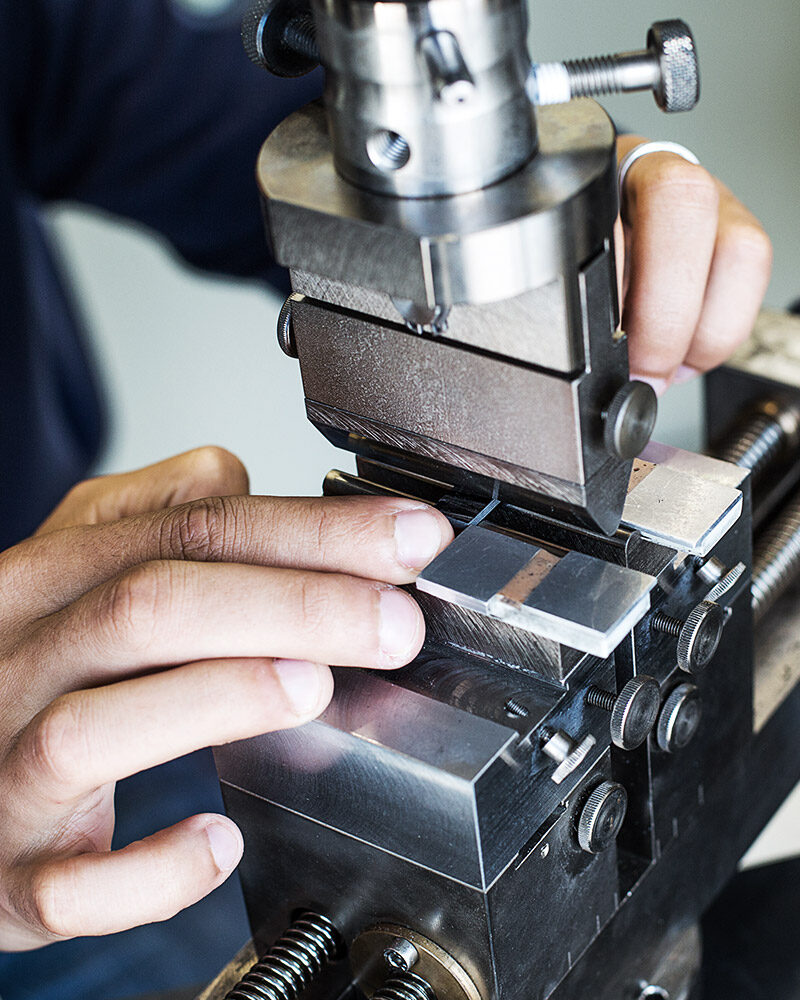

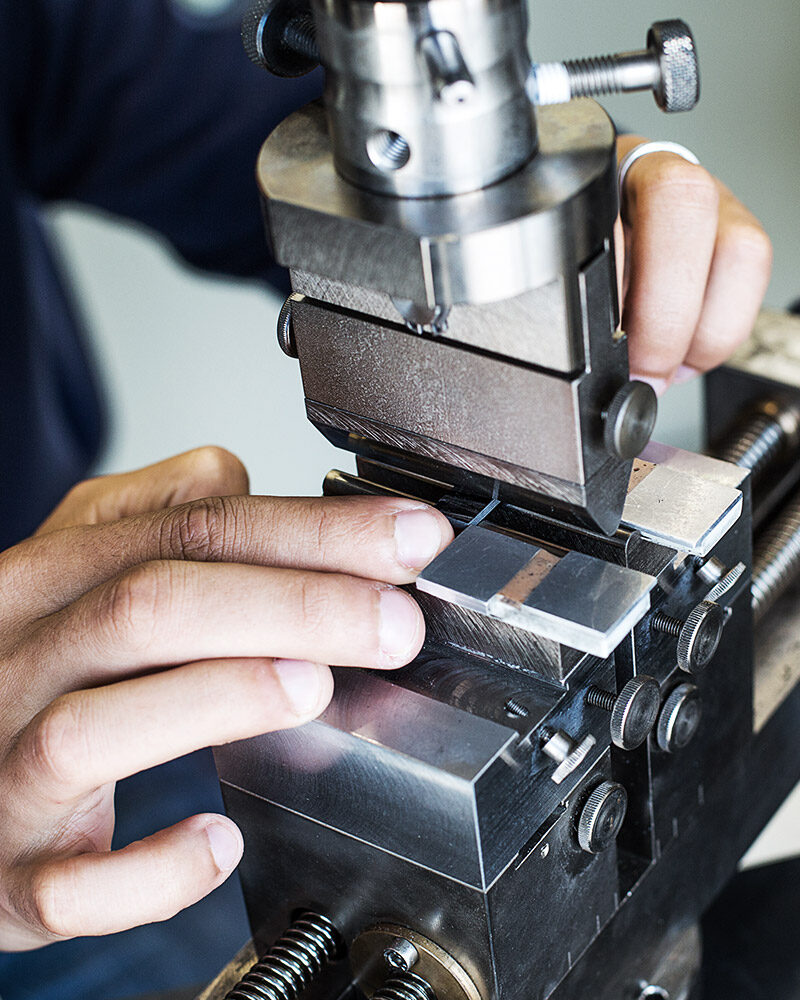

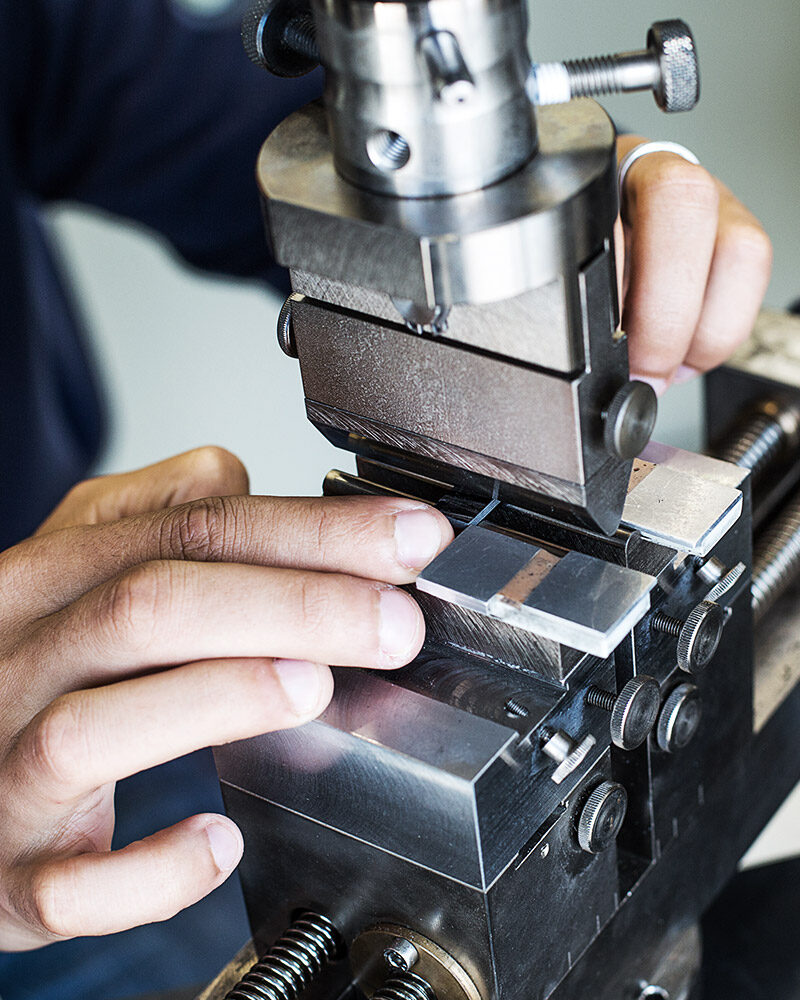

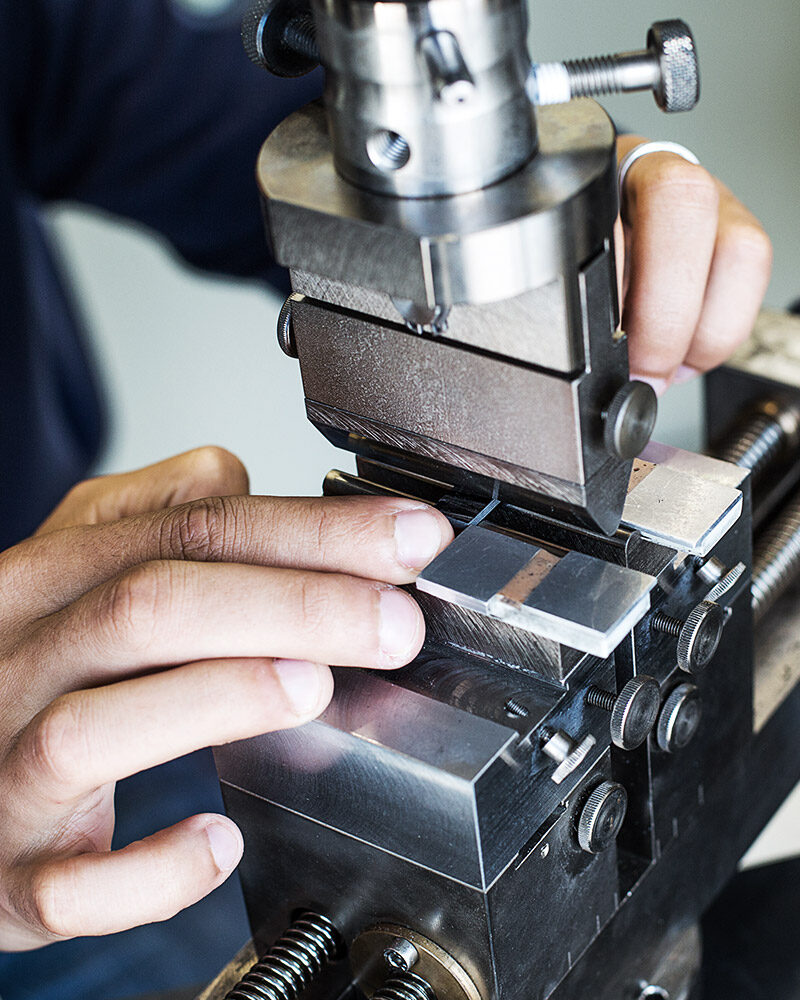

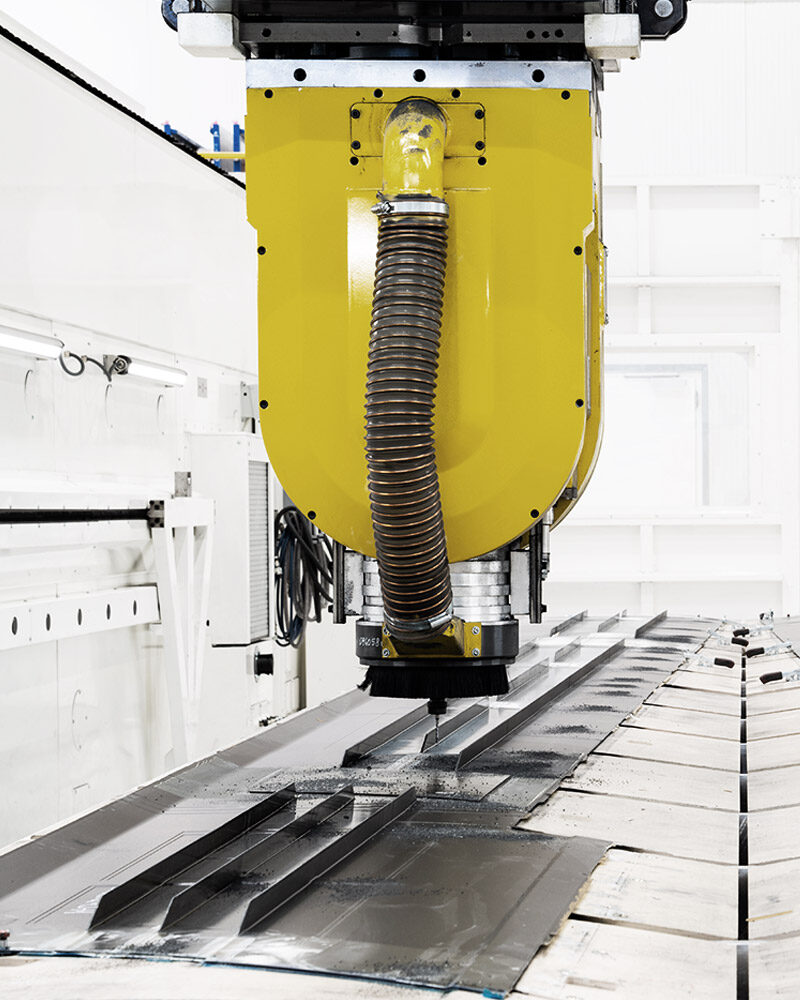

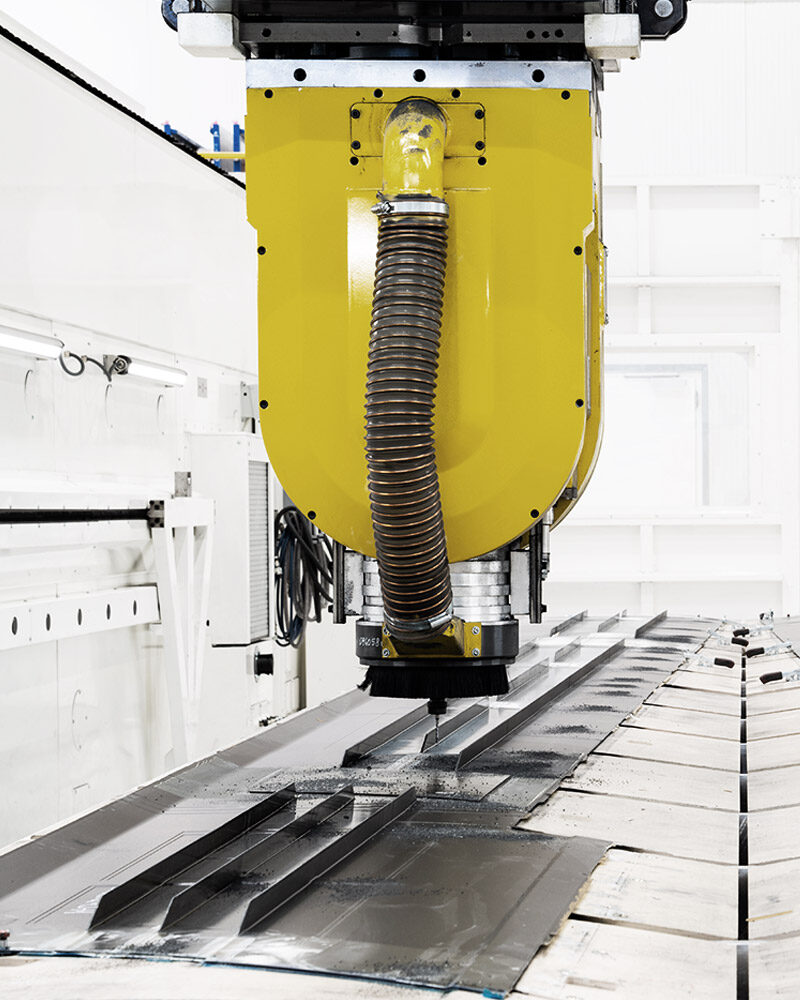

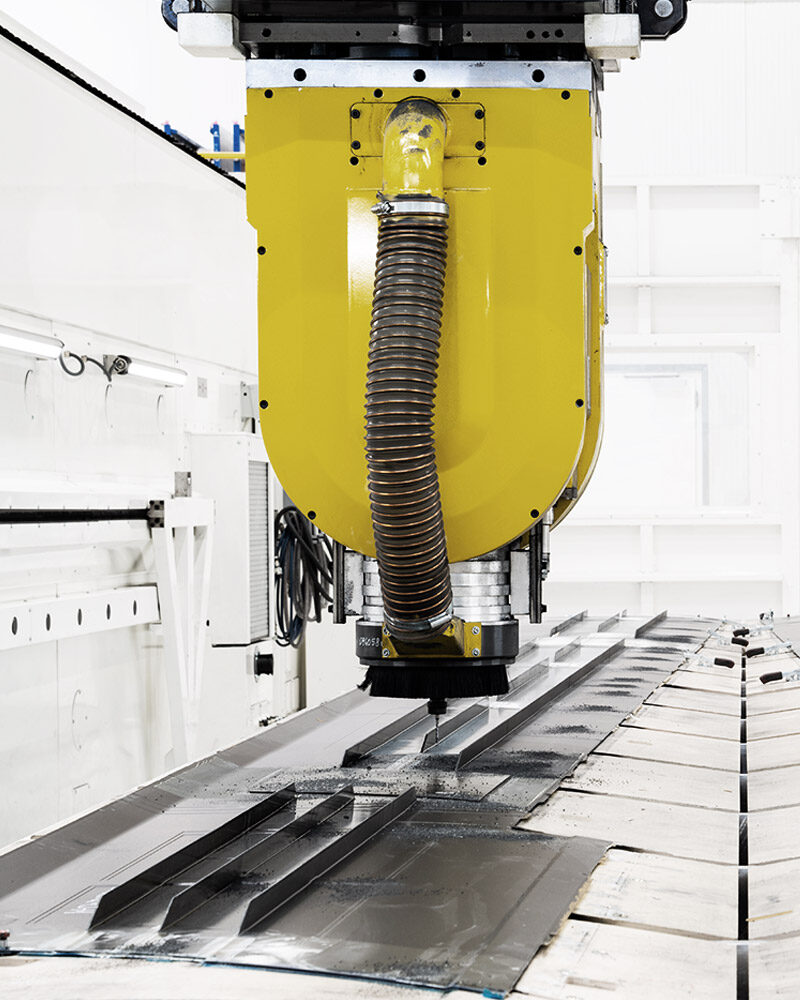

CNC Machining

Autoclave

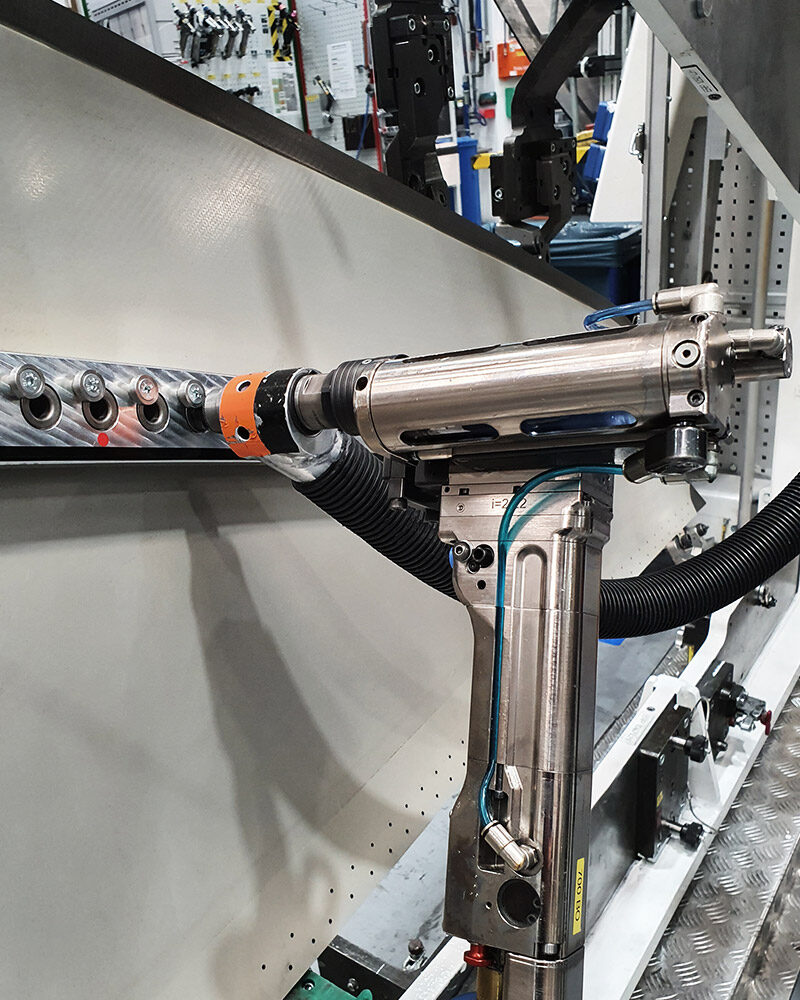

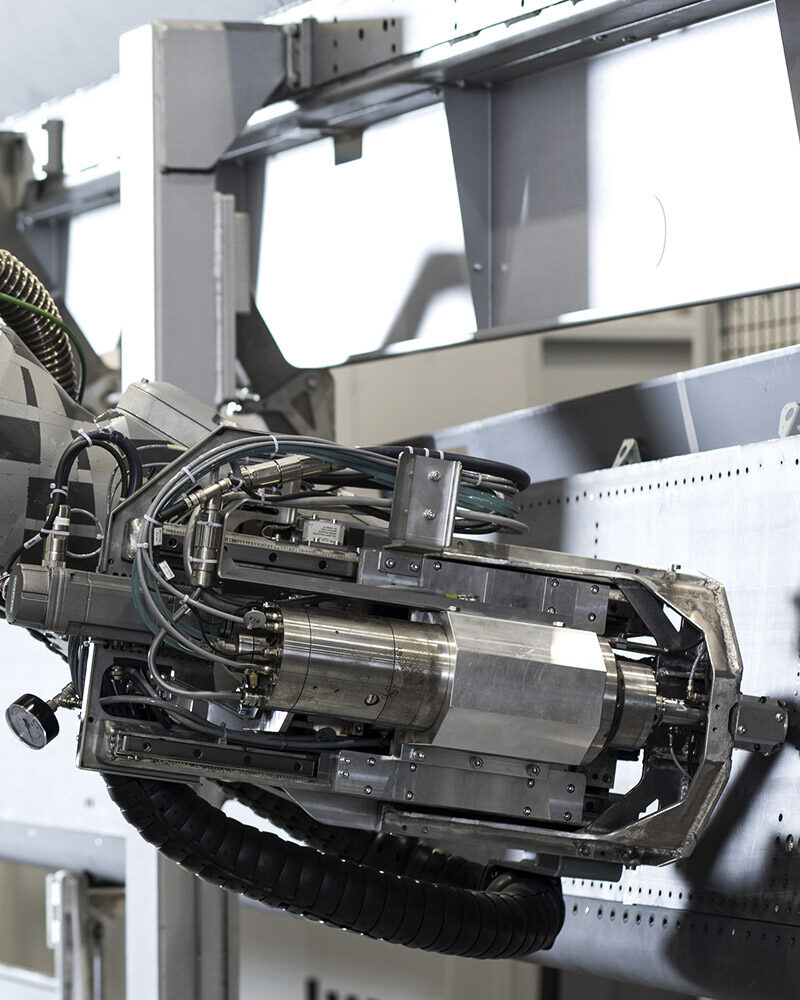

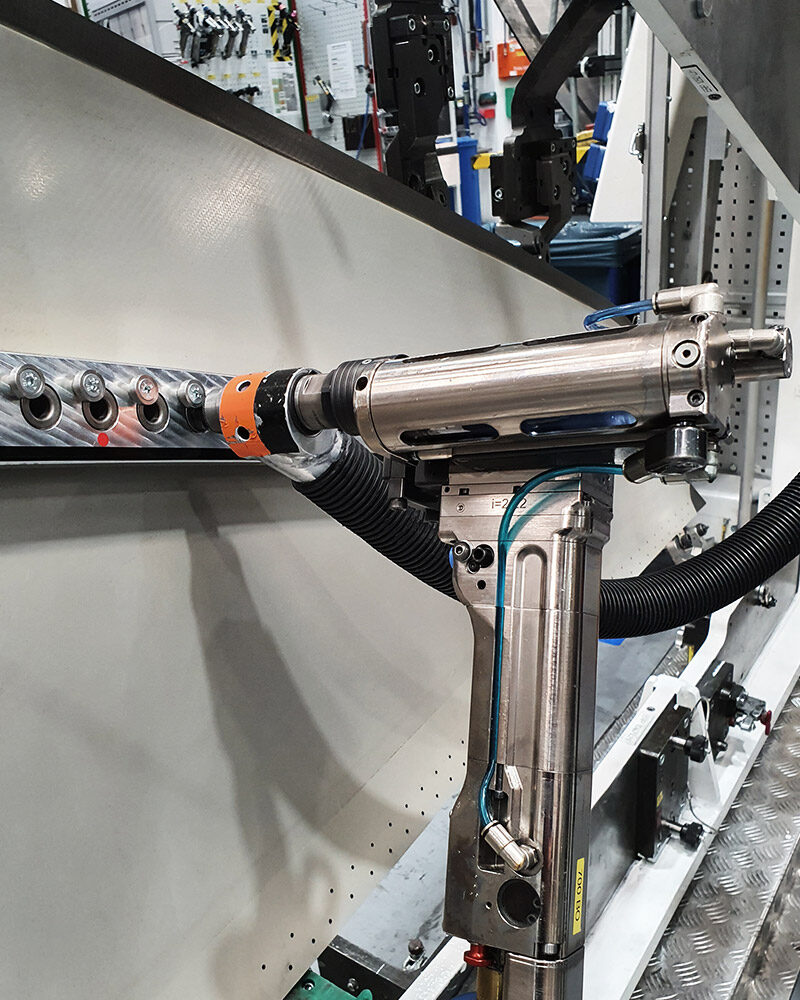

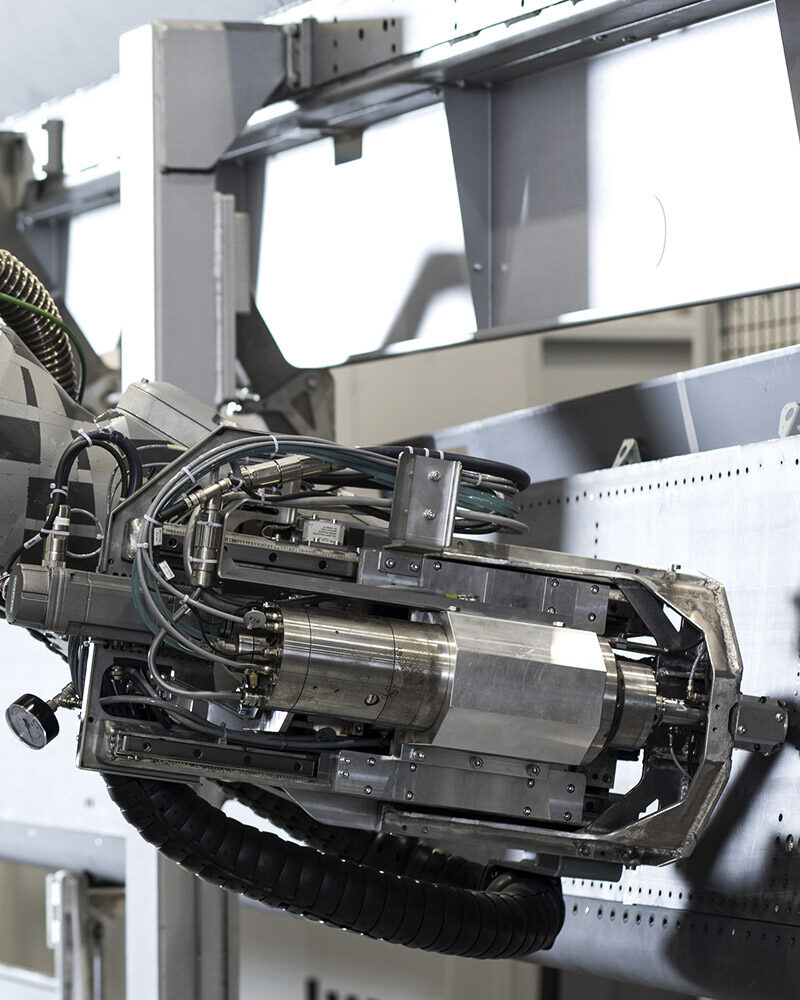

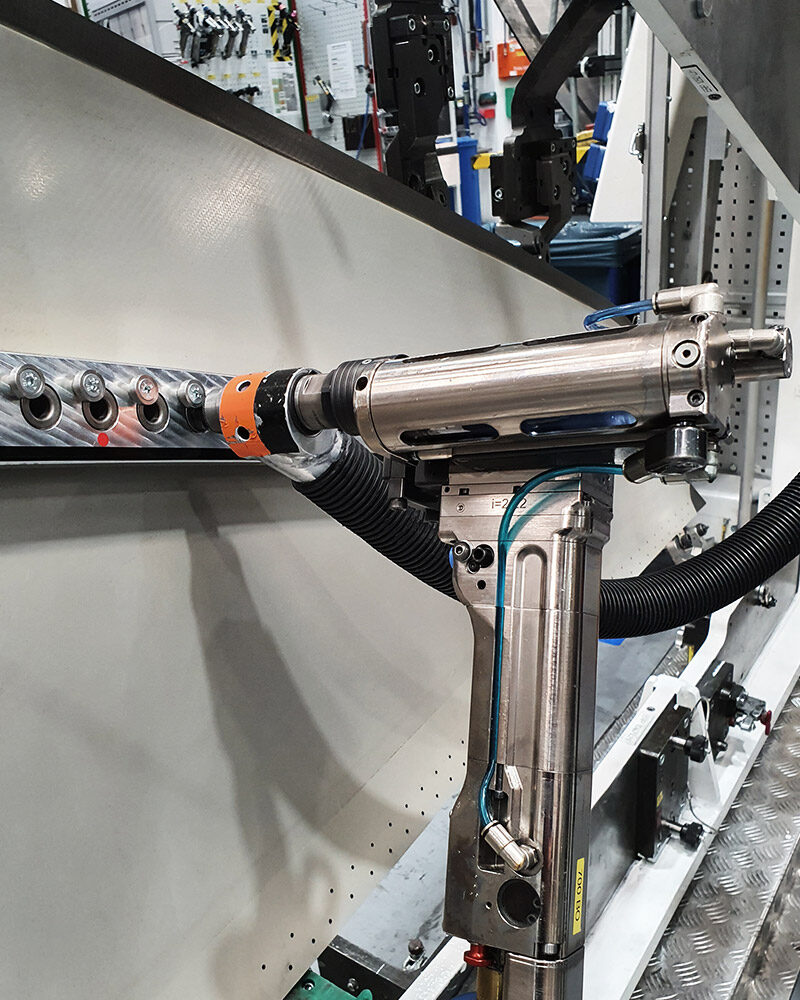

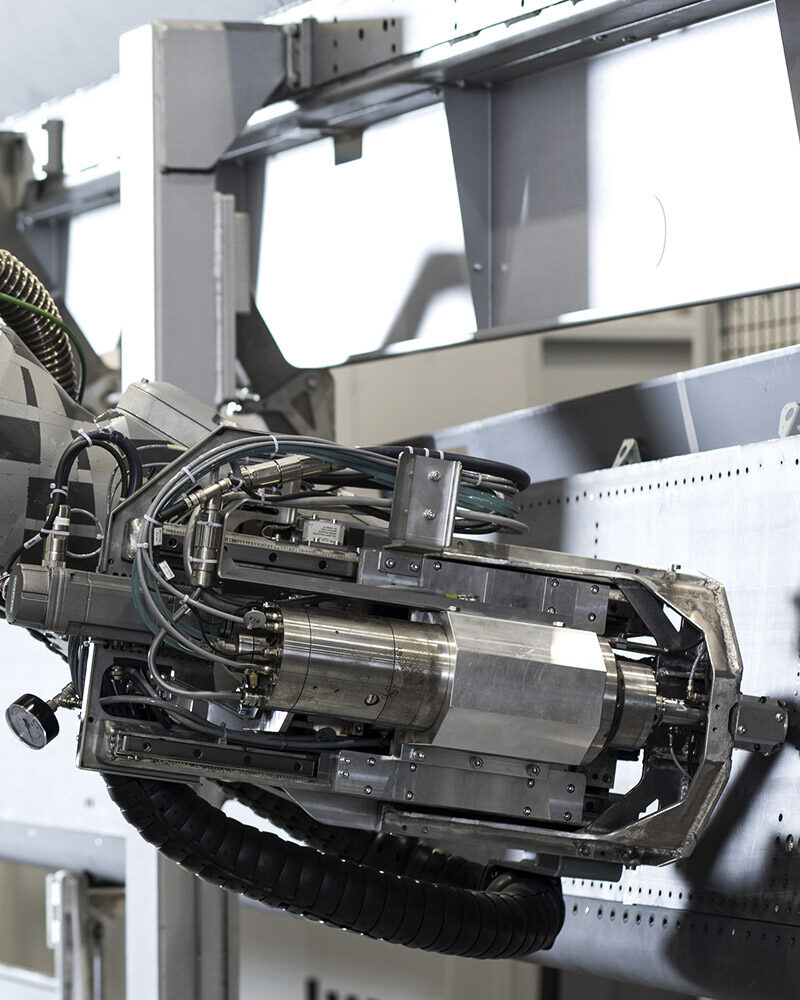

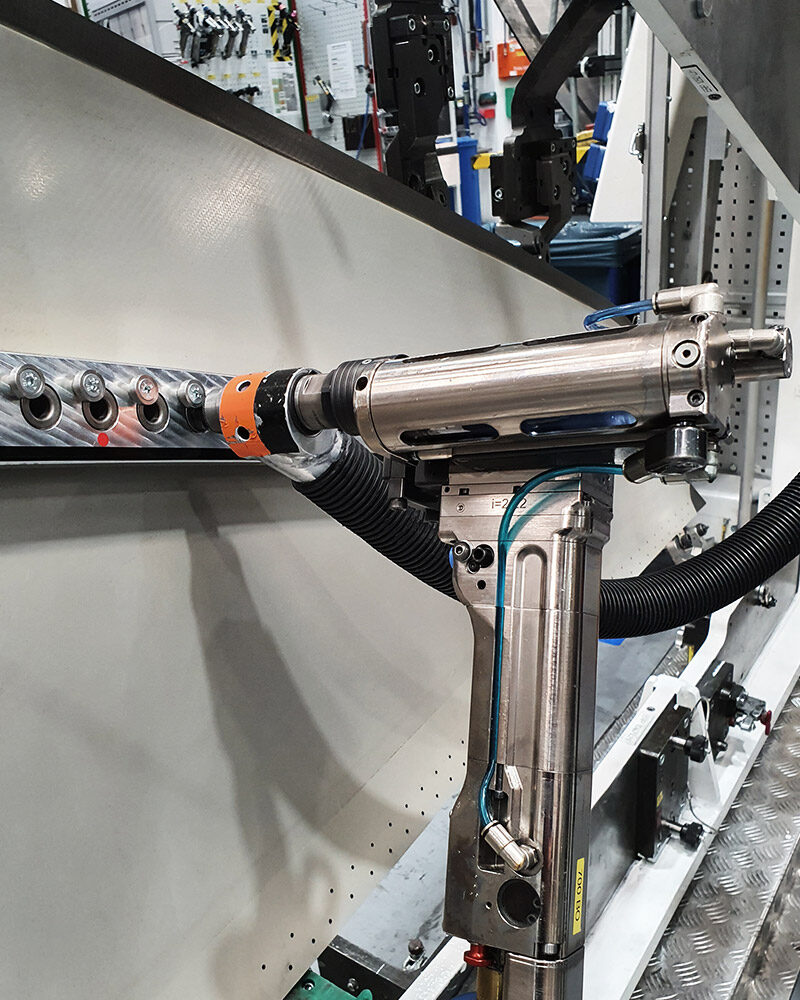

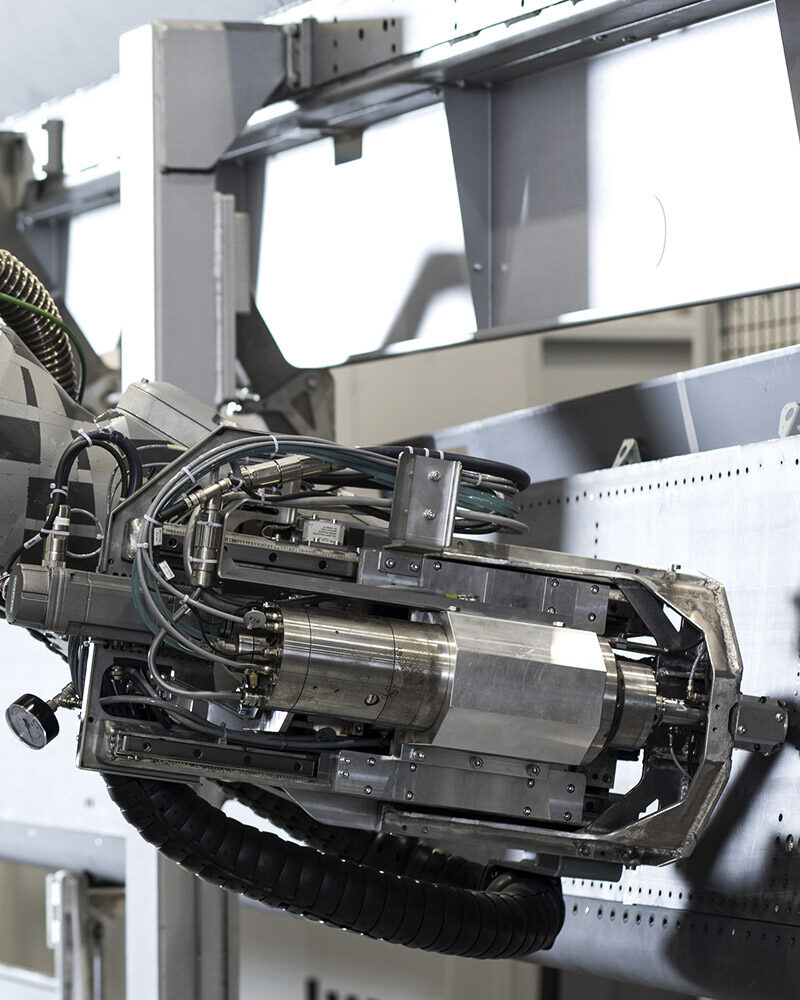

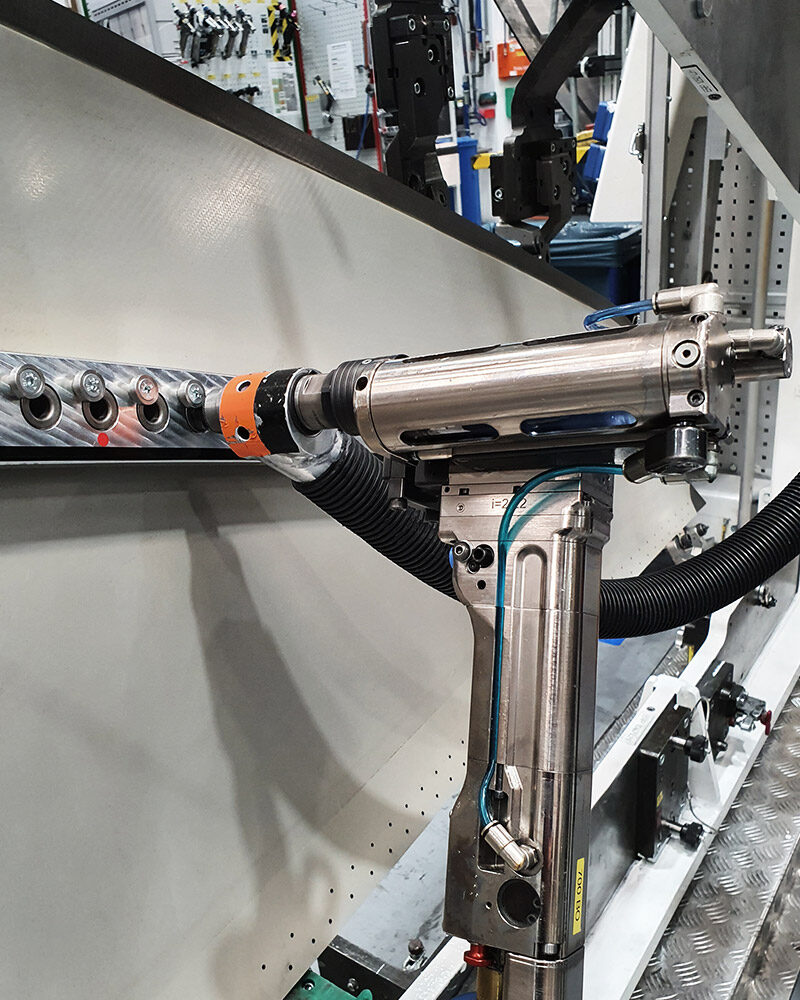

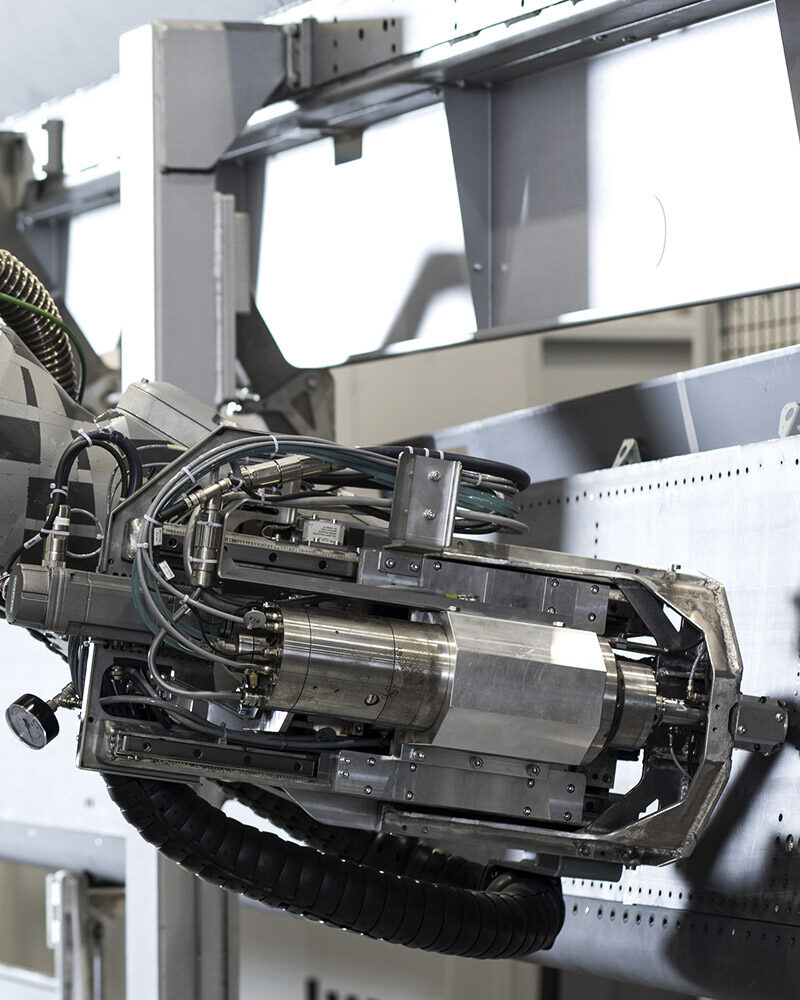

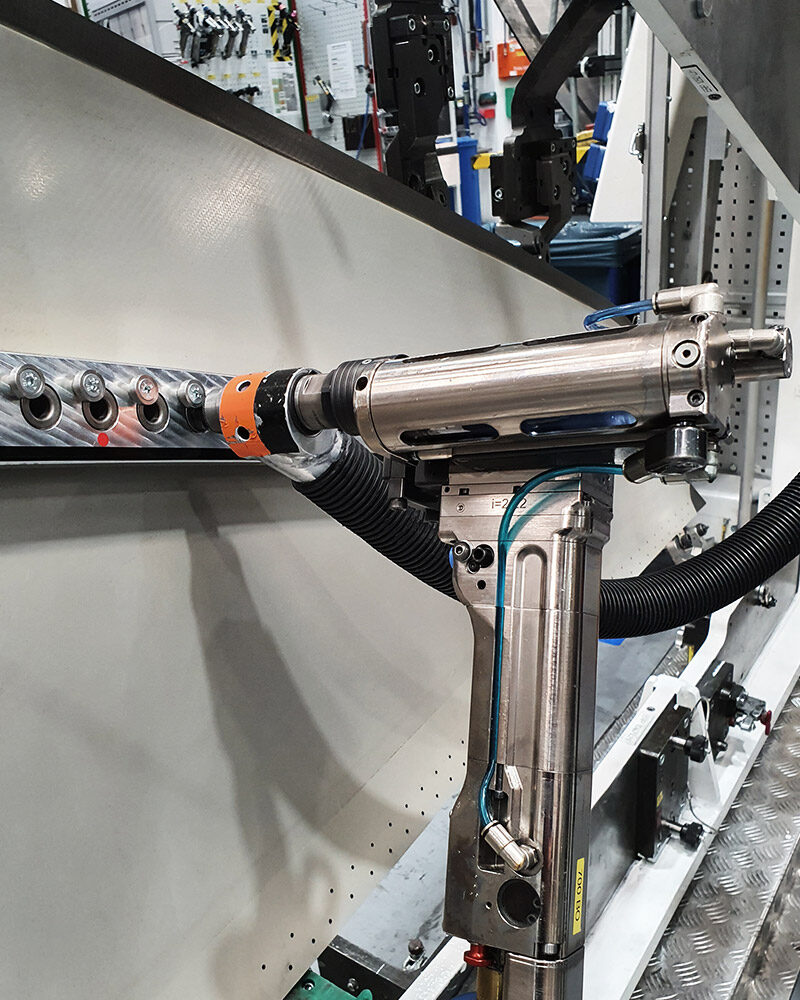

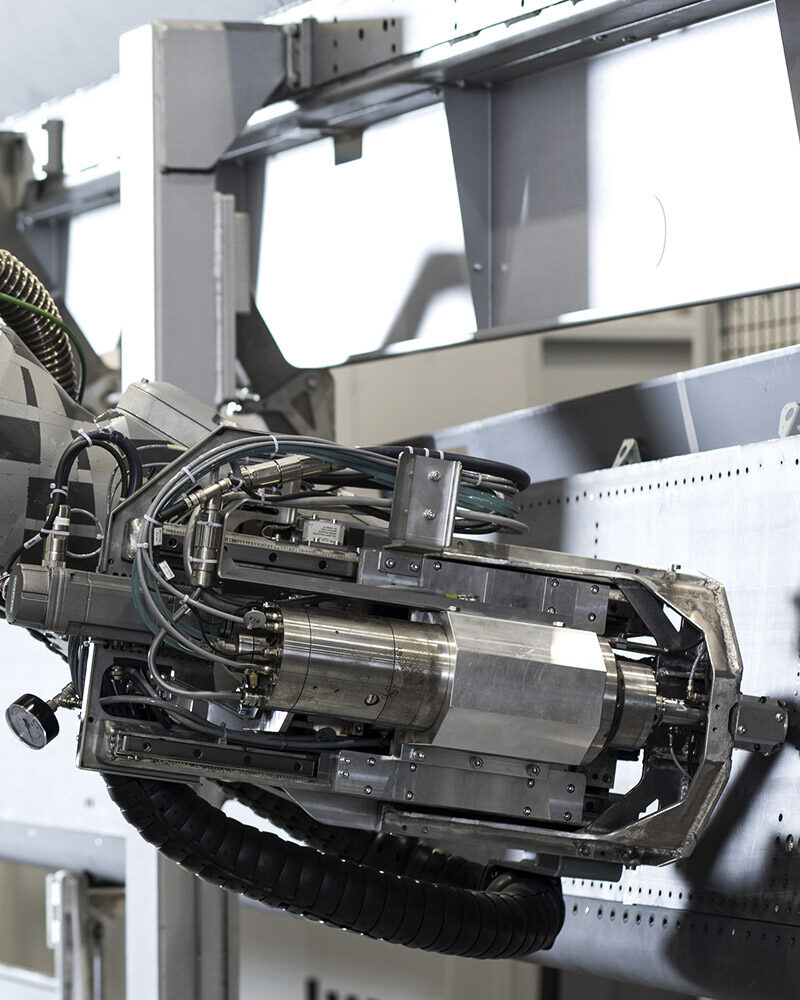

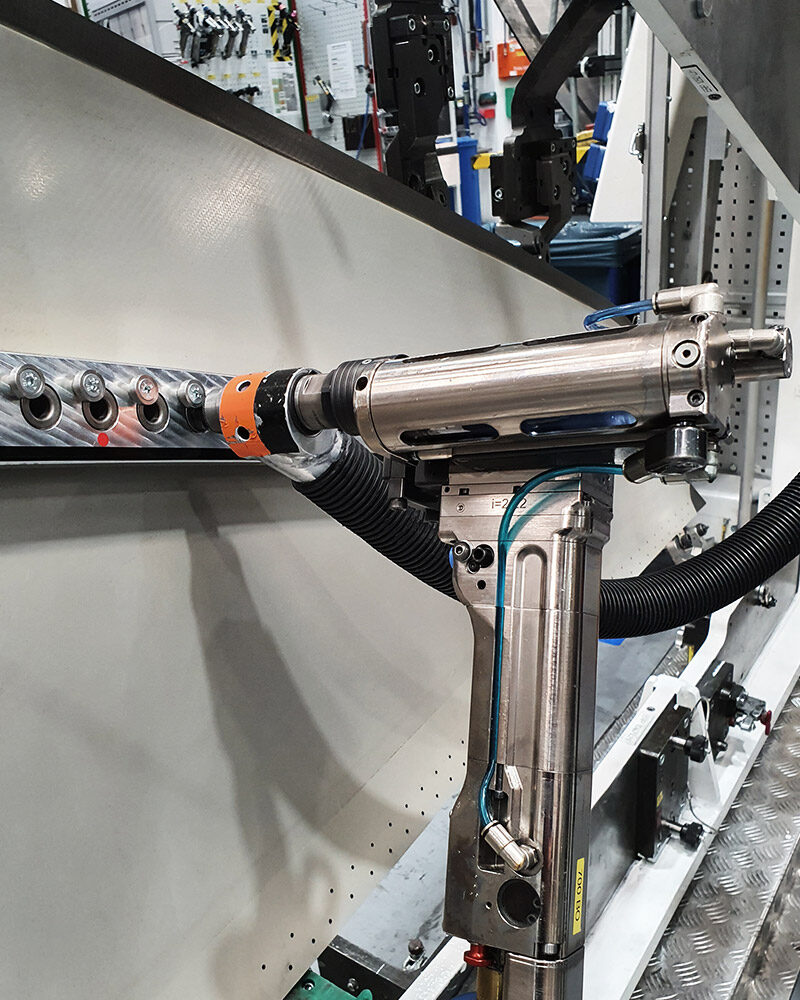

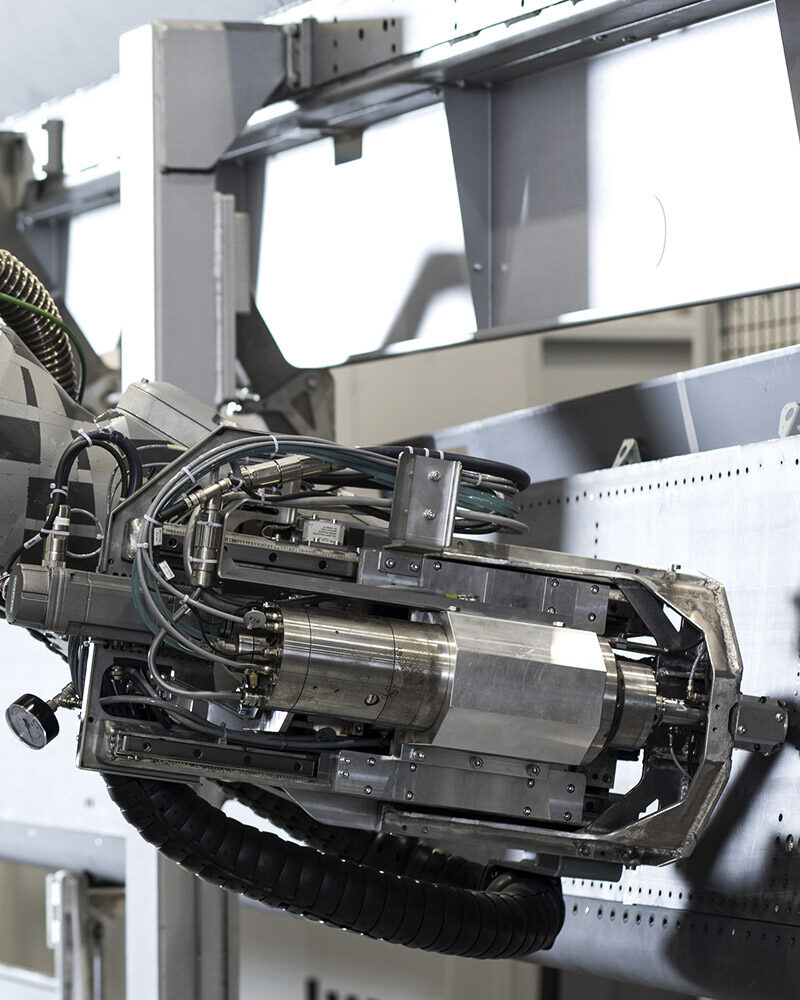

Robot drilling cell

Industrialization

Tooling

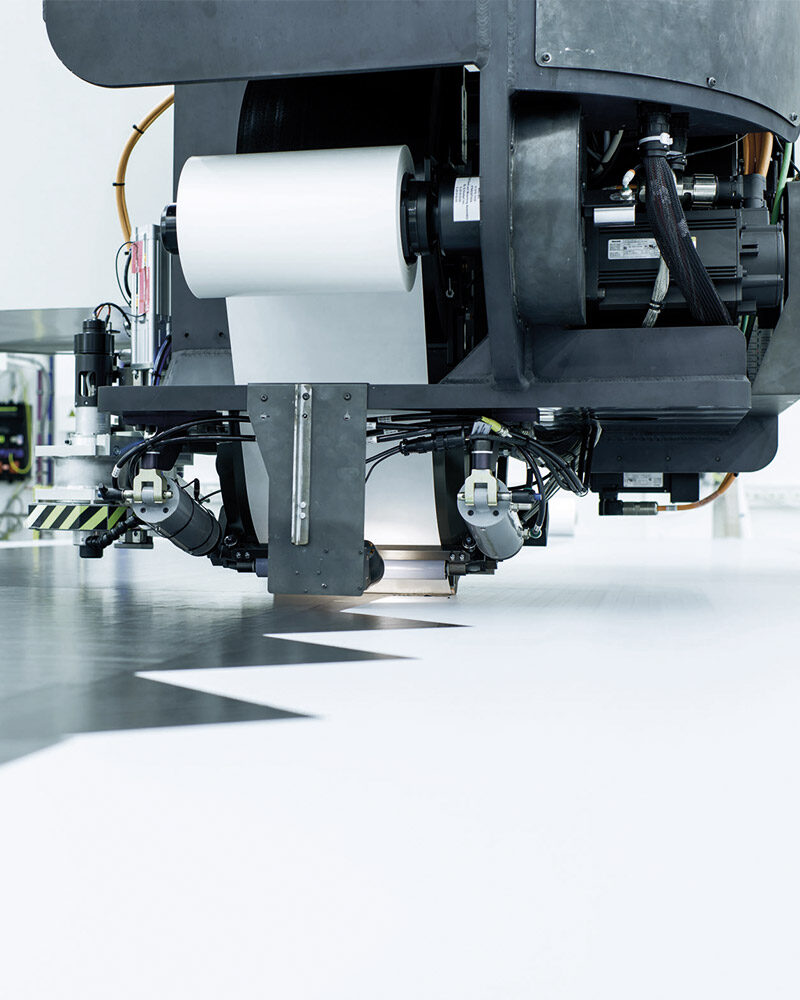

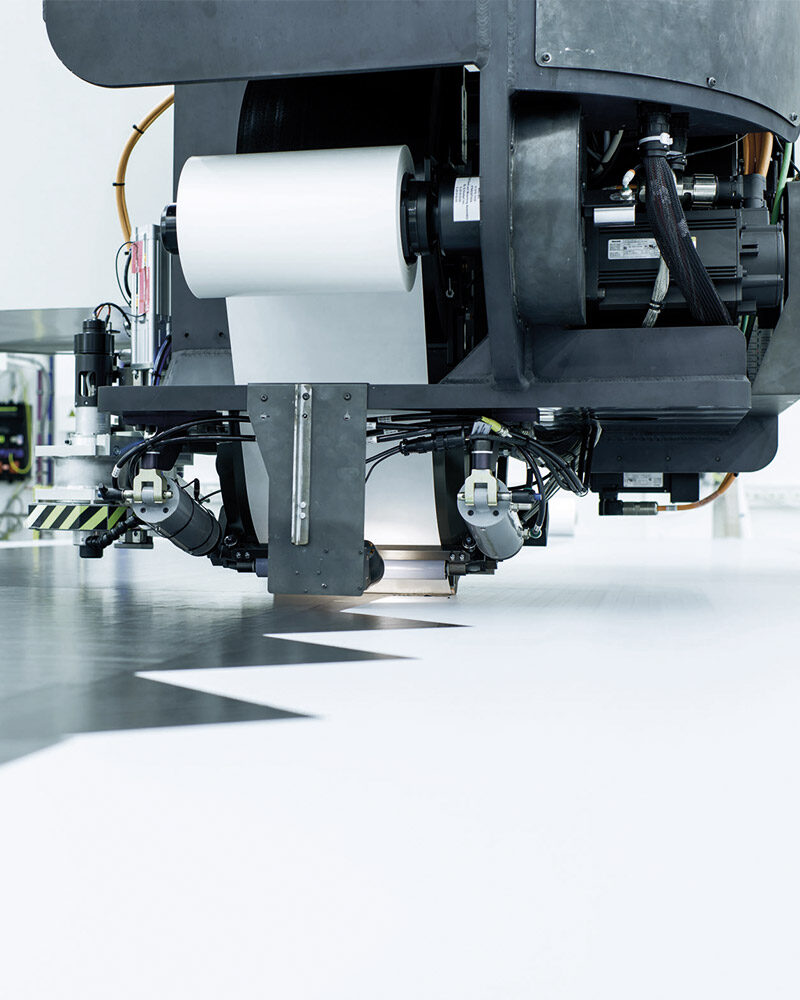

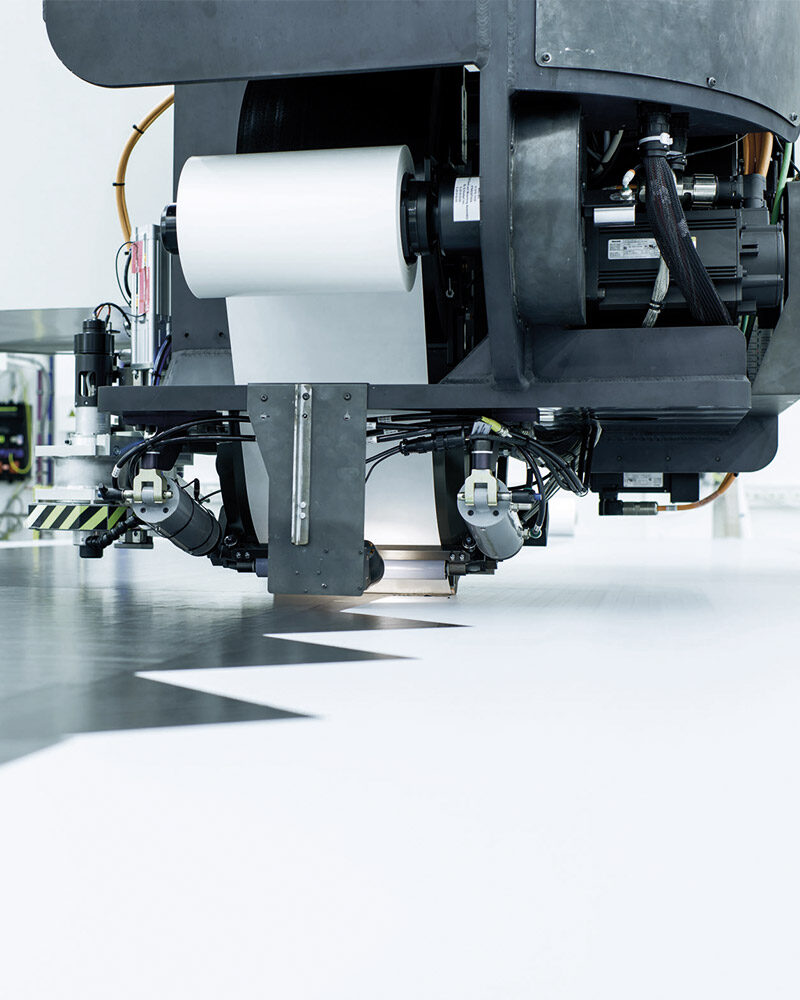

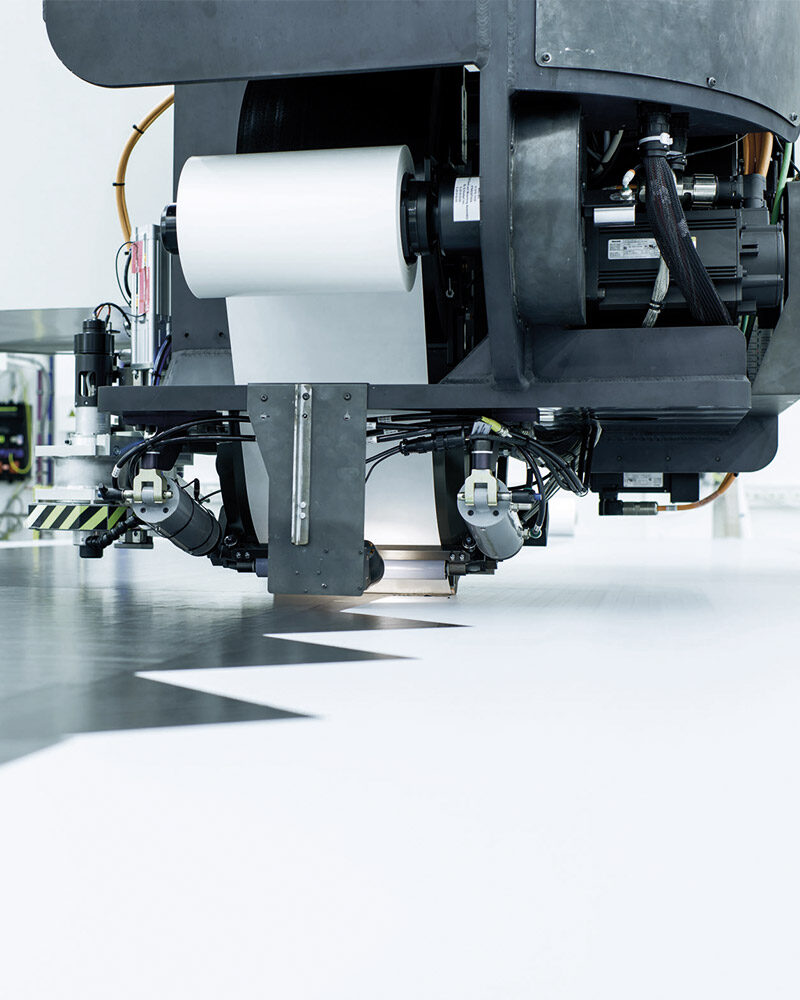

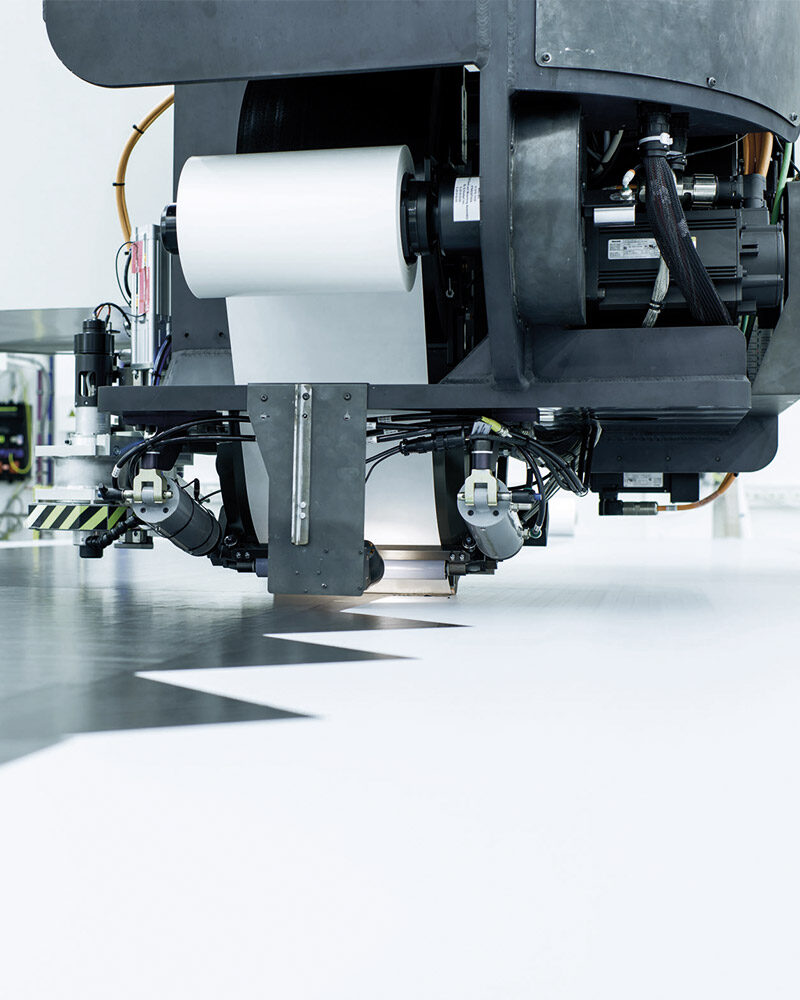

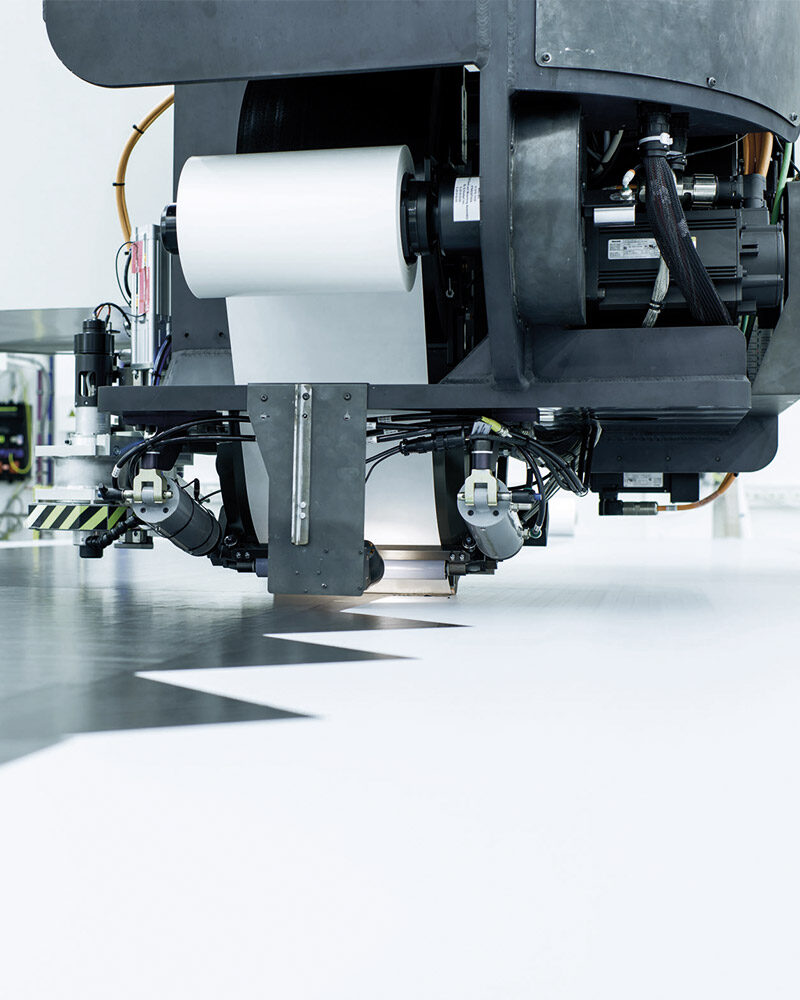

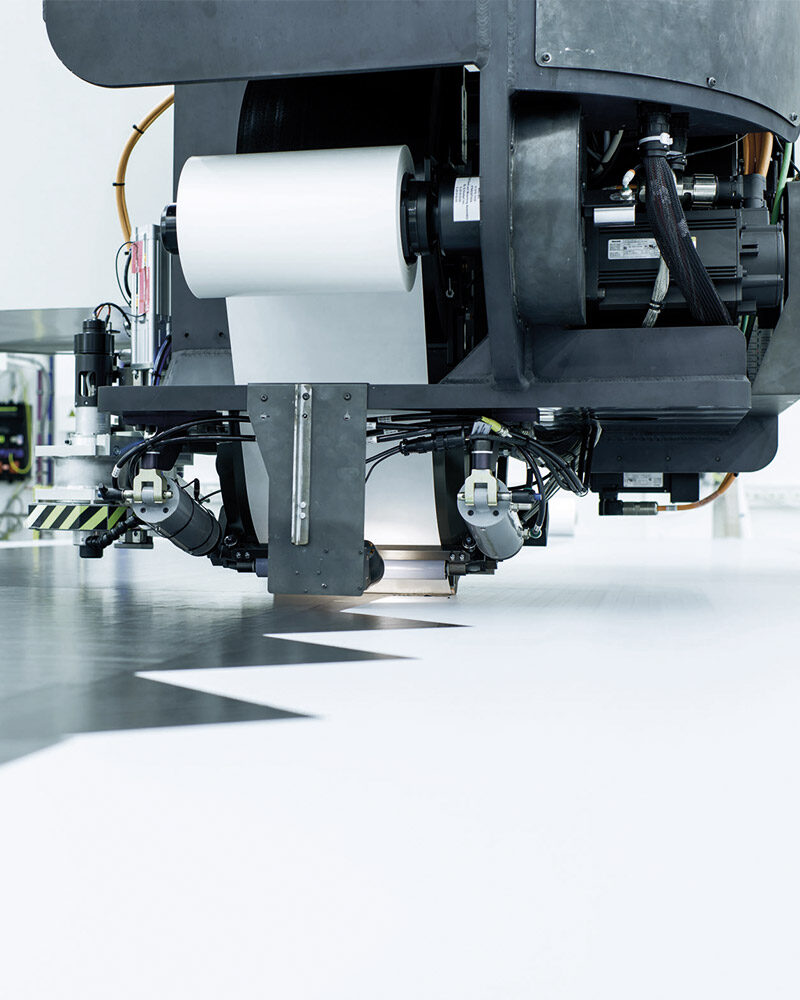

Automated Tape Laying

Hot Drape Forming

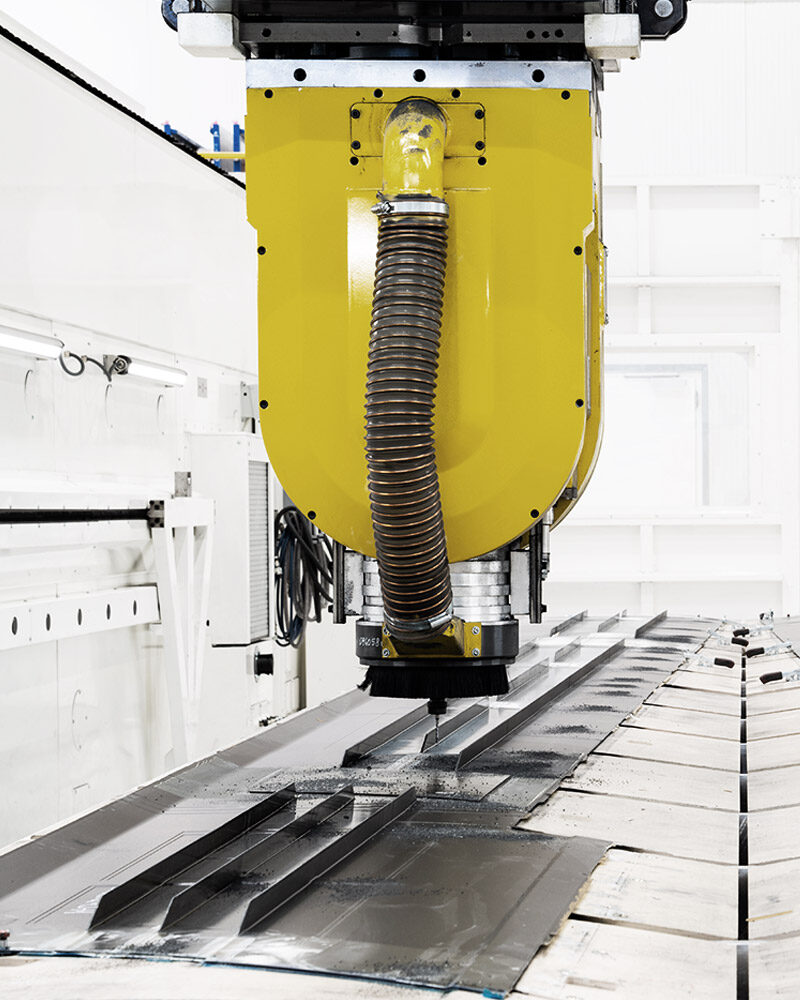

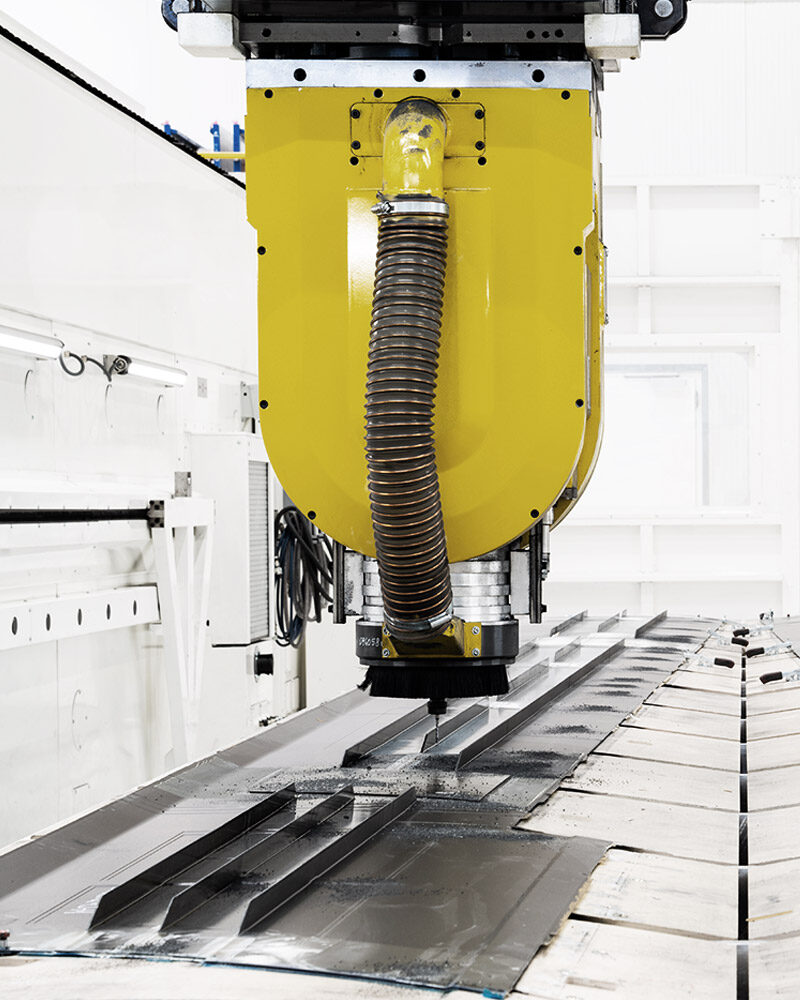

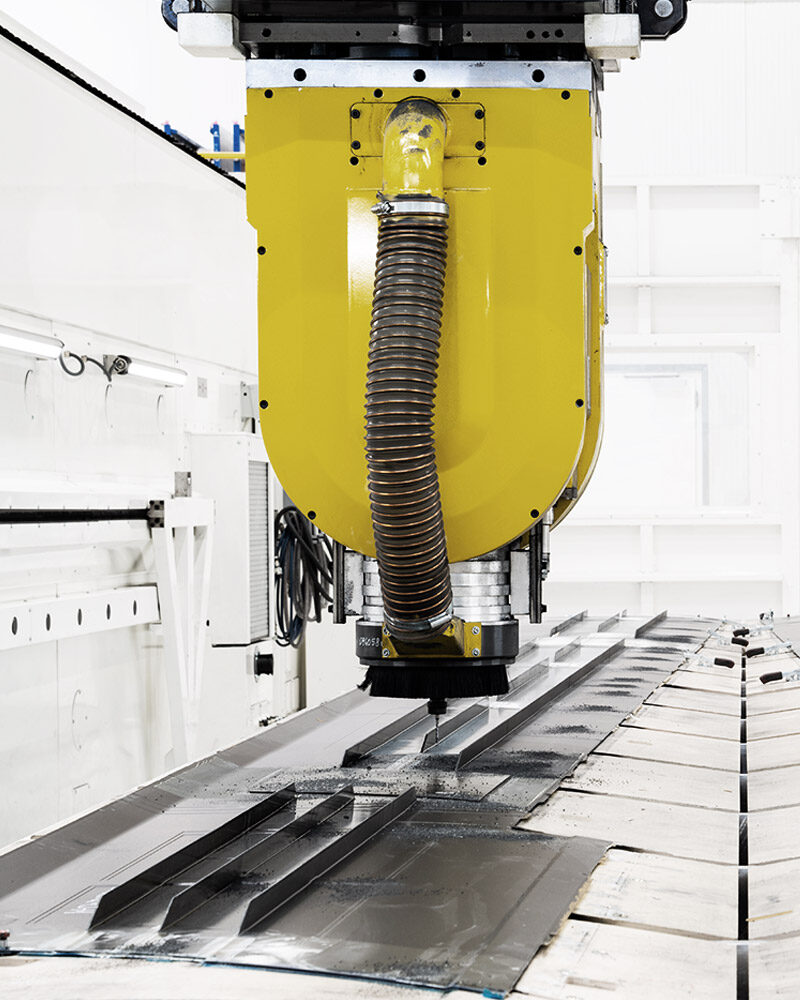

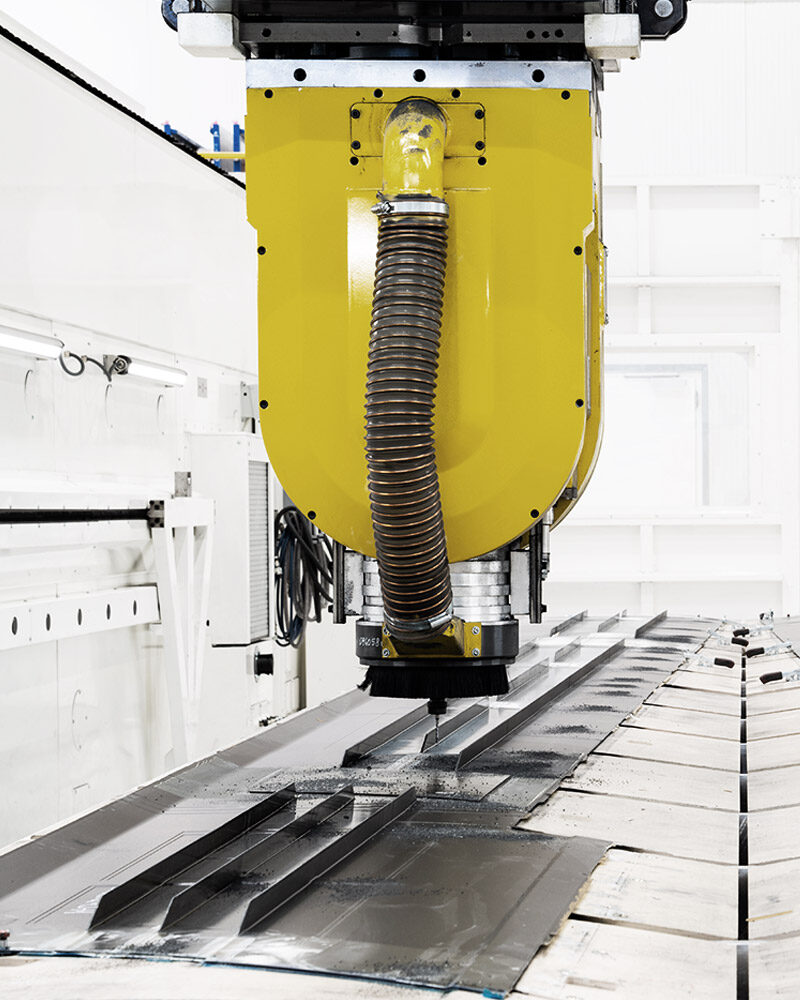

CNC Machining

Autoclave

Robot drilling cell

Industrialization

Tooling

Automated Tape Laying

Hot Drape Forming

CNC Machining

Autoclave

Robot drilling cell

Industrialization

Tooling

Automated Tape Laying

Hot Drape Forming

CNC Machining

Autoclave

Robot drilling cell

Industrialization

Tooling

Automated Tape Laying

Hot Drape Forming

CNC Machining

Autoclave

Robot drilling cell

Industrialization

Tooling

Automated Tape Laying

Hot Drape Forming

CNC Machining

Autoclave

Robot drilling cell

Industrialization

Tooling

Automated Tape Laying

Hot Drape Forming

CNC Machining

Autoclave

Robot drilling cell

Whenever possible, aircraft parts are repaired, minimizing the need for new production. Thanks to our triple competence (Part 21/J, Part 21/G, and Part 145), we perform repairs where others would be forced to scrap the part.

MRO Inspection

Composite Repair

Modifications

MRO Inspection

Composite Repair

Modifications

MRO Inspection

Composite Repair

Modifications

Quality, Environmental protection & occupational health safety

- FACC Safety & Quality Policy

- FACC Environmental Health and Safety Policy

- EN/AS 9100: Quality management for development, production, and service provision

- EN/AS 9110: Quality management for maintenance organizations

- ISO 14001: Environmental Management System

- ISO 45001: Occupational Health/Safety Management System